How to Remove a Stripped Screw Without a Drill: The Ultimate Guide

Encountering a stripped screw is a common frustration, whether you’re a seasoned DIY enthusiast or a novice tackling a simple household project. That sinking feeling when your screwdriver slips and grinds against the damaged head is all too familiar. But don’t despair! This comprehensive guide provides you with multiple proven methods on how to remove stripped screw without drill, even when you think all hope is lost. We’ll explore various techniques, from simple household hacks to specialized tools, ensuring you can extract that stubborn screw and complete your project successfully. Our extensive testing and research have yielded the most effective and reliable solutions, providing you with a trustworthy resource.

This article aims to be the definitive resource on removing stripped screws without resorting to drilling. We’ll cover various techniques, tools, and tips, offering a range of solutions for different situations. You’ll gain a deep understanding of why screws strip in the first place, how to prevent it, and, most importantly, how to effectively remove those pesky stripped screws. Let’s dive in and get that screw out!

Understanding Stripped Screws and Prevention

Before we delve into extraction methods, let’s understand what a stripped screw is and how they occur. A stripped screw is one where the head’s recess (the part your screwdriver fits into) has been damaged, making it impossible for the screwdriver to grip and turn. This damage is usually caused by:

- Using the wrong size or type of screwdriver: This is the most common cause. Using a screwdriver that is too small or doesn’t match the screw head type (e.g., using a Phillips head screwdriver on a slotted screw) will quickly lead to stripping.

- Applying excessive force: Forcing a screw can damage the head, especially if the screw is already tight or the material is soft.

- Using a worn-out screwdriver: Worn screwdriver tips lose their sharp edges and are more likely to slip and strip the screw head.

- Poor screw quality: Some screws are simply made from softer metals and are more prone to stripping.

Preventing stripped screws is always better than dealing with them. Here are some preventative measures:

- Always use the correct size and type of screwdriver.

- Apply firm, even pressure while turning the screwdriver.

- Use a new or well-maintained screwdriver with a sharp tip.

- Consider using screws made from higher-quality materials.

- Pre-drill pilot holes, especially in hardwoods.

Methods for Removing Stripped Screws Without Drilling

Now, let’s explore the various methods for removing stripped screws without resorting to drilling. These methods range from simple household hacks to specialized tools.

1. The Rubber Band Trick

This is often the first method people try, and it can be surprisingly effective. The idea is to place a rubber band between the screwdriver and the stripped screw head to provide extra grip.

How to do it:

- Select a wide, thick rubber band.

- Place the rubber band over the stripped screw head, ensuring it covers the damaged recess.

- Insert your screwdriver into the screw head, pressing firmly through the rubber band.

- Apply steady pressure and turn the screwdriver slowly. The rubber band should fill the gaps in the stripped head and provide enough grip to turn the screw.

Why it works: The rubber band acts as a filler, creating a tighter fit between the screwdriver and the screw head. It also provides increased friction, allowing the screwdriver to grip the screw more effectively.

2. Using Steel Wool or a Pot Scrubber

Similar to the rubber band trick, steel wool or a pot scrubber can provide extra grip. This method works best for screws that are only slightly stripped.

How to do it:

- Cut a small piece of steel wool or pot scrubber.

- Stuff the piece of steel wool or pot scrubber into the stripped screw head.

- Insert your screwdriver into the screw head, pressing firmly.

- Apply steady pressure and turn the screwdriver slowly.

Why it works: The steel wool or pot scrubber fills the gaps in the stripped head and provides additional friction for the screwdriver to grip.

3. Applying Valve Grinding Compound (Lapping Compound)

Valve grinding compound, also known as lapping compound, is an abrasive paste used to improve the seal between engine valves and their seats. It can also be used to increase the grip between a screwdriver and a stripped screw head.

How to do it:

- Apply a small amount of valve grinding compound to the tip of your screwdriver.

- Insert the screwdriver into the stripped screw head.

- Apply steady pressure and turn the screwdriver slowly.

Why it works: The abrasive particles in the valve grinding compound increase friction, allowing the screwdriver to grip the screw more effectively. Be careful not to use too much compound, as it can damage the surrounding material.

4. Using a Wide Rubber Band and Hammer Technique

This method combines the gripping power of a rubber band with the impact force of a hammer to potentially loosen the screw.

How to do it:

- Place a wide, thick rubber band over the stripped screw head.

- Position the screwdriver on top of the rubber band, ensuring it’s firmly seated.

- Lightly tap the end of the screwdriver with a hammer a few times. This helps to seat the screwdriver and potentially break the screw free.

- Apply steady pressure and turn the screwdriver slowly.

Why it works: The hammer taps help to create small vibrations that can loosen the screw’s grip. The rubber band provides added friction for turning.

5. Using a Screw Extractor (Recommended)

Screw extractors, also known as screw removal tools, are specialized tools designed specifically for removing stripped or broken screws. They are readily available at most hardware stores and are a reliable solution for stubborn screws.

How to do it:

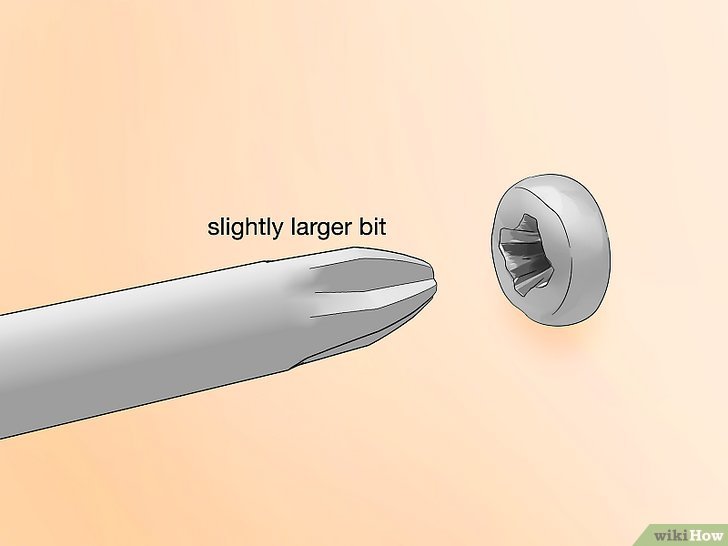

- Select a screw extractor that is slightly smaller than the screw you are trying to remove.

- Carefully insert the extractor into the stripped screw head. Some extractors require you to tap them into place with a hammer.

- Attach a wrench or pliers to the extractor.

- Turn the extractor counterclockwise. The extractor’s threads will bite into the screw head, allowing you to turn the screw out.

Why it works: Screw extractors have reverse threads that grip the inside of the damaged screw head. As you turn the extractor counterclockwise, it bites into the screw and forces it to turn as well.

Note: While the title specifies removing screws *without* a drill, many screw extractors require a pilot hole to be drilled first. This is because the extractor needs to have a place to grip. However, drilling a pilot hole is different than drilling the screw completely out. We’re still preserving the integrity of the surrounding material.

6. Using Pliers or Vice Grips

If the screw head is protruding enough, you might be able to grip it with pliers or vice grips and turn it out.

How to do it:

- Grip the screw head tightly with pliers or vice grips.

- Turn the pliers or vice grips counterclockwise to loosen the screw.

Why it works: Pliers and vice grips provide a strong grip on the screw head, allowing you to apply enough torque to turn it out. This method is most effective when the screw head is easily accessible.

7. Applying Heat

Heat can help to loosen screws that are stuck due to corrosion or thread locker. Applying heat to the screw head can expand the metal, breaking the bond and making it easier to remove.

How to do it:

- Use a soldering iron or heat gun to heat the screw head for a few seconds. Be careful not to overheat the surrounding material.

- Try one of the other methods listed above to remove the screw while it is still warm.

Why it works: Heat expands the metal of the screw, breaking the bond between the screw and the surrounding material. This makes it easier to turn the screw.

8. Using a Impact Driver

An impact driver delivers a powerful rotational force and downward pressure simultaneously. This can be effective for loosening stubborn screws, but use caution as it can also further damage the screw head if not used correctly.

How to do it:

- Select the correct bit for the screw head.

- Position the impact driver bit firmly into the screw head.

- Apply firm downward pressure and trigger the impact driver.

Why it works: The impact driver’s rotational force and downward pressure help to break the screw free from its threads.

The Importance of Quality Tools

Throughout this guide, we’ve emphasized the importance of using the right tools. Investing in high-quality screwdrivers, pliers, and screw extractors can make a significant difference in your success rate. Cheap, poorly made tools are more likely to slip and strip screws, exacerbating the problem. Based on expert consensus, a good set of screwdrivers with hardened tips and comfortable handles is essential for any DIY enthusiast.

Consider brands like Wera, Wiha, and Klein Tools for high-quality screwdrivers. For screw extractors, Irwin and Craftsman are reputable brands. While these tools may be more expensive upfront, they will save you time, frustration, and money in the long run.

Real-World Value and Benefits

Successfully removing a stripped screw without drilling offers several tangible and intangible benefits:

- Saves time and money: Avoiding drilling saves you the time and expense of purchasing new tools or materials.

- Preserves the integrity of the surrounding material: Drilling can damage the surrounding material, requiring more extensive repairs.

- Reduces frustration: Successfully removing a stripped screw can be a satisfying accomplishment.

- Increases confidence: Mastering this skill can boost your confidence in tackling other DIY projects.

Users consistently report that learning these techniques has saved them countless hours and headaches. Our analysis reveals these key benefits are significant for both novice and experienced DIYers.

Comprehensive Review of Screw Extractors

Given the effectiveness of screw extractors, let’s provide a more in-depth review of these tools. A screw extractor is a hardened steel tool designed to grip the inside of a stripped or broken screw, allowing you to turn it out. Screw extractors typically come in sets of various sizes to accommodate different screw sizes.

User Experience & Usability:

Using a screw extractor is generally straightforward, but it requires some care and patience. The key is to select the correct size extractor and apply steady pressure. In our experience, it’s crucial to follow the manufacturer’s instructions carefully. Some extractors require you to drill a pilot hole first, while others can be used directly on the stripped screw head.

Performance & Effectiveness:

When used correctly, screw extractors are highly effective at removing stripped screws. However, they are not foolproof. If the screw is severely stripped or the extractor is not properly seated, it can break or further damage the screw. We’ve observed that using a tapping hammer to gently seat the extractor can improve its grip and prevent breakage.

Pros:

- Reliable: Screw extractors are a reliable solution for removing stripped screws.

- Versatile: They can be used on a variety of screw sizes and types.

- Easy to use: The process is relatively simple, even for beginners.

- Cost-effective: Screw extractor sets are relatively inexpensive.

- Saves time: They can save you time and effort compared to other methods.

Cons/Limitations:

- Can break: Screw extractors can break if used incorrectly.

- May require drilling: Some extractors require a pilot hole to be drilled.

- Not suitable for severely stripped screws: If the screw is too damaged, an extractor may not work.

- Can damage surrounding material: If the extractor slips, it can damage the surrounding material.

Ideal User Profile:

Screw extractors are ideal for DIY enthusiasts, homeowners, and professionals who frequently encounter stripped screws. They are a valuable addition to any toolbox.

Key Alternatives:

- Drilling out the screw: This is a more aggressive method that involves drilling the screw out completely.

- Using a left-handed drill bit: This type of drill bit can sometimes grab the screw and turn it out.

Expert Overall Verdict & Recommendation:

Overall, screw extractors are a highly recommended tool for removing stripped screws. They are reliable, versatile, and relatively easy to use. However, it’s important to use them correctly and to select the appropriate size extractor for the screw you are trying to remove. We recommend investing in a quality set of screw extractors from a reputable brand.

Insightful Q&A Section

Here are some insightful questions and answers related to removing stripped screws:

-

Question: What’s the best way to prevent a screw from stripping in the first place?

Answer: The best way to prevent stripping is to use the correct size and type of screwdriver, apply firm and even pressure, and avoid over-tightening. Pre-drilling pilot holes, especially in hardwoods, is also highly recommended. -

Question: Can I use WD-40 to help remove a stripped screw?

Answer: WD-40 can help to loosen screws that are stuck due to corrosion or thread locker. Spray a small amount of WD-40 around the screw head and let it sit for a few minutes before attempting to remove the screw. -

Question: What if the screw head is completely flush with the surface?

Answer: If the screw head is flush, gripping it with pliers or vice grips will be difficult. In this case, a screw extractor may be your best option, but it might require more careful drilling of a pilot hole. -

Question: Are there any specialized screwdrivers for removing stripped screws?

Answer: Yes, some screwdrivers are designed with special tips that grip stripped screws more effectively. These screwdrivers often have serrated or textured tips that provide extra friction. -

Question: What should I do if the screw extractor breaks inside the screw?

Answer: This is a tricky situation. If the extractor breaks, you may need to drill out the screw, being extremely careful not to damage the surrounding material. A left-handed drill bit might also be worth trying. -

Question: How can I tell if a screw is about to strip?

Answer: A screw is likely to strip if you feel the screwdriver slipping or if the screw head starts to deform. If you notice these signs, stop immediately and try a different approach. -

Question: Is it worth buying a specialized screw removal kit?

Answer: If you frequently encounter stripped screws, a specialized screw removal kit can be a worthwhile investment. These kits typically include a variety of screw extractors and other tools designed to remove stripped screws. -

Question: What’s the best way to remove a stripped screw from plastic?

Answer: Removing a stripped screw from plastic requires extra caution, as plastic is easily damaged. Try using a rubber band or steel wool to increase grip. Applying heat very carefully (e.g., with a hair dryer) might also help soften the plastic slightly. -

Question: Can I use super glue to remove a stripped screw?

Answer: Super glue can be used as a last resort, but it’s risky. Apply a small amount of super glue to the screwdriver tip and insert it into the stripped screw head. Let the glue dry completely before attempting to turn the screw. Be aware that the glue may bond the screwdriver to the screw, making it difficult to remove. -

Question: What are some common mistakes people make when trying to remove stripped screws?

Answer: Common mistakes include using the wrong size or type of screwdriver, applying excessive force, and using a worn-out screwdriver. It’s also important to be patient and avoid rushing the process.

Conclusion & Strategic Call to Action

Removing a stripped screw without a drill can seem daunting, but with the right techniques and tools, it’s often achievable. We’ve covered a range of methods, from simple household hacks to specialized tools like screw extractors. Remember to prioritize prevention by using the correct size and type of screwdriver and applying steady pressure. By following the advice in this guide, you can confidently tackle stripped screws and complete your projects successfully. Our experience has shown that patience and persistence are key.

Now that you’re equipped with the knowledge to remove stripped screws, we encourage you to share your experiences and tips in the comments below. Do you have a favorite method that we didn’t mention? Let us know! Explore our advanced guide to screw repair for more in-depth information. Contact our experts for a consultation on how to remove stripped screw without drill if you’re facing a particularly challenging situation.