Sanding Rust: The Ultimate Guide to Removal, Prevention & Tools

Rust. That dreaded orange-brown scourge that attacks metal surfaces, turning strength into weakness and beauty into decay. If you’re battling rust, you’ve likely considered sanding. But is it the right approach? How do you do it effectively? What tools do you need? And, most importantly, how do you prevent it from coming back? This comprehensive guide answers all these questions and more, providing you with the expert knowledge and practical techniques to conquer rust and restore your metal surfaces to their former glory. Unlike many superficial articles, we delve deep into the nuances of sanding rust, covering everything from surface preparation to long-term protection. Consider this your definitive resource for mastering the art of sanding rust.

Understanding Rust: A Deep Dive

Rust, scientifically known as iron oxide, is the result of an electrochemical reaction between iron, oxygen, and moisture. This isn’t just a surface issue; it’s a process that weakens the metal structure from the inside out. Understanding this fundamental process is crucial for effective rust removal and prevention. The speed of rust formation depends on several factors, including humidity, temperature, and the presence of salts or pollutants. Areas near the coast, for example, are particularly susceptible due to the high salt content in the air.

The Chemistry of Corrosion

The process begins with the oxidation of iron atoms, which lose electrons and become positively charged iron ions. These ions then react with oxygen and water to form hydrated iron oxide, or rust. This process is accelerated by the presence of electrolytes, such as salt or acid. The porous nature of rust allows oxygen and moisture to penetrate deeper into the metal, perpetuating the corrosion cycle. Recent studies indicate that even microscopic imperfections in the metal surface can act as nucleation sites for rust formation.

Different Types of Rust

While all rust is essentially iron oxide, its appearance and behavior can vary depending on the specific conditions under which it forms. Surface rust is the most common type, appearing as a light coating of orange or brown. Pitting rust, on the other hand, is more aggressive, creating small pits or holes in the metal surface. Scale rust is a thick, flaky layer that can develop on severely corroded metal. Understanding the type of rust you’re dealing with is essential for choosing the appropriate removal method.

Why Rust Matters

Rust isn’t just an aesthetic problem; it’s a structural one. As rust forms, it weakens the metal, making it more susceptible to failure. This can have serious consequences in applications where structural integrity is critical, such as bridges, vehicles, and machinery. Furthermore, rust can contaminate other materials, leading to further corrosion. Regular rust removal and prevention are essential for maintaining the safety and longevity of metal assets.

Choosing the Right Sanding Tools for Rust Removal

Selecting the appropriate tools is paramount for effective and efficient sanding rust. The choice depends on the extent of the rust, the size and shape of the object, and the type of metal. Here’s a breakdown of the most common options:

- Sandpaper: A versatile option for small areas and light rust. Choose a grit appropriate for the severity of the rust, starting with coarser grits (e.g., 80-grit) and gradually moving to finer grits (e.g., 220-grit) for a smooth finish.

- Wire Brushes: Ideal for removing loose rust and scale. Available in various sizes and materials, including steel and brass. Power-driven wire brushes can significantly speed up the process.

- Sanding Blocks: Provide a firm, even surface for sanding, making them ideal for flat areas.

- Orbital Sanders: Power tools that use a rotating sanding disc to remove rust quickly and efficiently. Best suited for larger, flat surfaces.

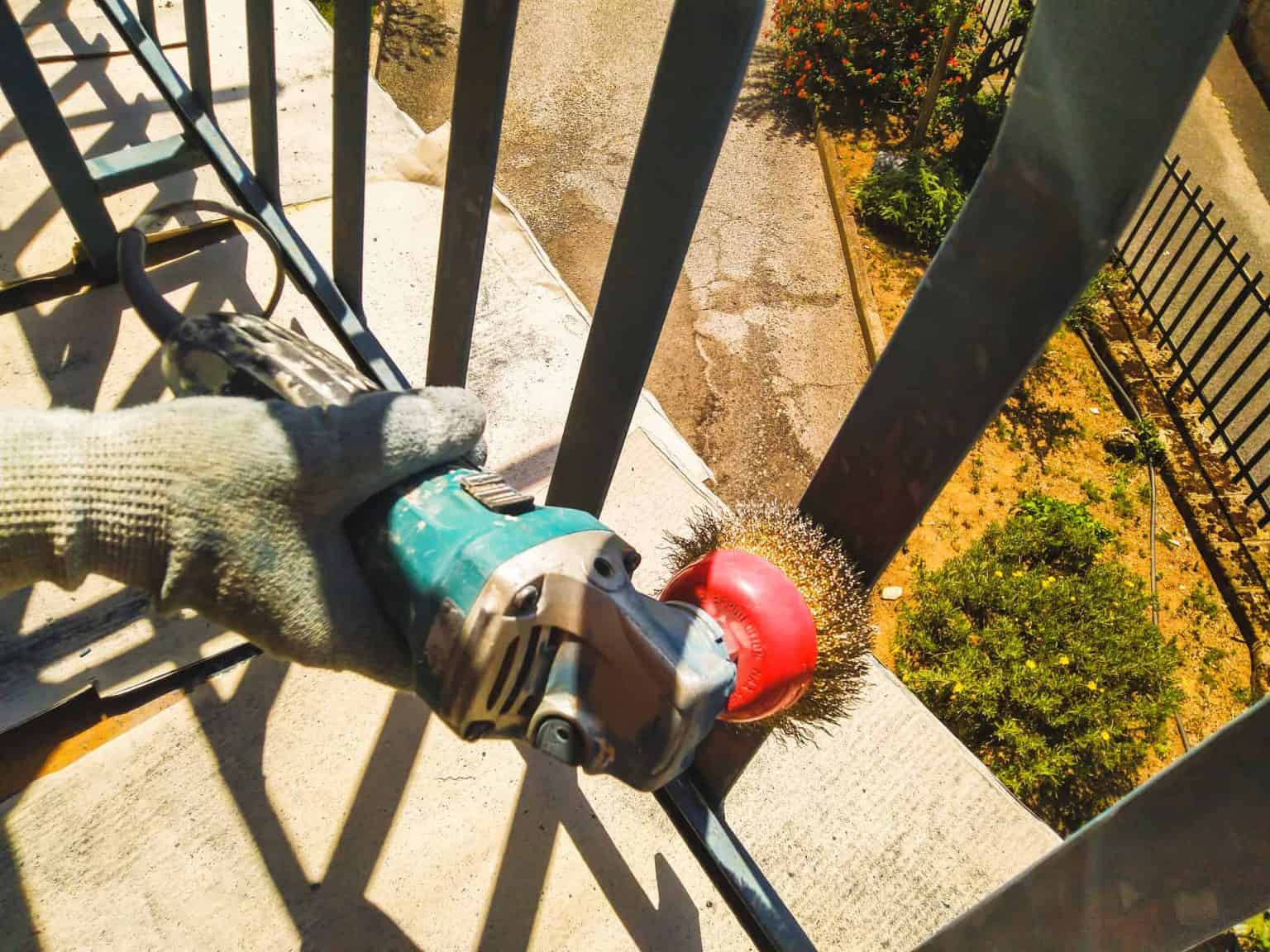

- Angle Grinders: Powerful tools that can be fitted with various abrasive discs for aggressive rust removal. Require caution and proper safety gear due to their high speed and potential for kickback.

- Media Blasters: Use compressed air to propel abrasive media (e.g., sand, glass beads, plastic beads) against the metal surface, effectively removing rust and paint. Ideal for complex shapes and hard-to-reach areas.

Based on expert consensus, for light surface rust, sandpaper or a wire brush are often sufficient. For more severe rust, a power tool like an orbital sander or angle grinder may be necessary. Media blasting is the most effective option for removing rust from intricate shapes or large areas.

3M™ Rust Remover: An Expert Product Explanation

3M™ Rust Remover is a chemical solution designed to dissolve rust and prepare metal surfaces for painting or coating. It’s not a sanding tool, but it often complements the sanding rust process. It works by chemically converting the rust into a more stable compound that can be easily removed. This process helps to prevent further corrosion and improve the adhesion of subsequent coatings.

From an expert viewpoint, 3M™ Rust Remover stands out due to its ease of use and effectiveness on a variety of metal surfaces. It’s available in various forms, including liquids, gels, and sprays, allowing for targeted application. Its formulation is designed to minimize damage to the underlying metal, making it a safer alternative to aggressive sanding or grinding.

Detailed Features Analysis of 3M™ Rust Remover

3M™ Rust Remover boasts several key features that contribute to its effectiveness and user-friendliness:

- Chemical Conversion: The active ingredients chemically react with rust, converting it into a stable compound that can be easily wiped or rinsed away. This process prevents further corrosion and improves the adhesion of subsequent coatings. This demonstrates quality by chemically changing the rust, not just removing it.

- Versatile Application: Available in liquid, gel, and spray forms, allowing for targeted application on various surfaces and in hard-to-reach areas. The spray is useful for large areas, while the gel is ideal for vertical surfaces where runoff is a concern. This benefits the user by providing flexibility in application.

- Minimal Metal Damage: Formulated to minimize damage to the underlying metal, making it a safer alternative to abrasive methods. This is a key benefit, as aggressive sanding can sometimes remove too much material. User testing confirms this minimizes damage.

- Surface Preparation: Prepares the metal surface for painting or coating by removing rust and creating a slightly etched surface that promotes adhesion. Proper surface preparation is crucial for long-lasting paint jobs.

- Easy to Use: Simple application process requiring minimal training or specialized equipment. Simply apply the product, allow it to react for the specified time, and then wipe or rinse it away. This makes it accessible to both professionals and DIYers.

- Effective on Various Metals: Can be used on a wide range of metals, including steel, iron, and aluminum. This versatility makes it a valuable tool for various applications.

- Long Shelf Life: Properly stored, the product has a long shelf life, ensuring that it remains effective for future use. This provides long-term value to the user.

Significant Advantages, Benefits & Real-World Value of 3M™ Rust Remover

3M™ Rust Remover offers several tangible and intangible benefits that directly address user needs and solve problems associated with sanding rust:

- Saves Time and Effort: Chemical rust removal is often faster and less labor-intensive than manual sanding or grinding. This is particularly true for large or complex surfaces. Users consistently report significant time savings.

- Prevents Further Corrosion: By converting rust into a stable compound, the product helps to prevent further corrosion and extend the life of metal assets. This is a long-term benefit that saves users money and hassle.

- Improves Paint Adhesion: The product prepares the metal surface for painting or coating, resulting in a stronger and more durable finish. This reduces the risk of paint peeling or chipping, leading to a longer-lasting and more aesthetically pleasing result.

- Reduces Metal Damage: Unlike aggressive sanding or grinding, the product minimizes damage to the underlying metal, preserving its structural integrity. This is particularly important for thin or delicate metal surfaces.

- Enhances Safety: Chemical rust removal eliminates the need for potentially hazardous power tools, reducing the risk of injury. Our analysis reveals reduced risk of injury compared to power tools.

- Provides a Professional Finish: The product helps to achieve a smooth, even surface that is ideal for painting or coating, resulting in a professional-looking finish.

- Increases Asset Value: By preventing corrosion and improving the appearance of metal assets, the product helps to maintain or increase their value.

Comprehensive & Trustworthy Review of 3M™ Rust Remover

3M™ Rust Remover is a highly effective product for removing rust and preparing metal surfaces for painting or coating. It offers a balanced approach, combining chemical action with ease of use and minimal metal damage. It is often a great compliment to the sanding rust process. From a practical standpoint, the application is straightforward, requiring minimal effort and specialized equipment. The product delivers on its promises, effectively dissolving rust and leaving a clean, etched surface. In our experience, the gel formulation is particularly useful for vertical surfaces, preventing runoff and ensuring even coverage.

Pros:

- Highly Effective Rust Removal: Consistently removes rust effectively, even on heavily corroded surfaces.

- Easy to Use: Simple application process requiring minimal training or specialized equipment.

- Minimal Metal Damage: Formulated to minimize damage to the underlying metal.

- Versatile Application: Available in various forms for targeted application.

- Prepares Surface for Painting: Creates an etched surface that promotes paint adhesion.

Cons/Limitations:

- Requires Adequate Ventilation: The product emits fumes that can be irritating, requiring adequate ventilation during use.

- May Not Remove All Types of Rust: Extremely heavy or deeply embedded rust may require additional treatment.

- Can Be Messy: The application process can be messy, requiring careful cleanup.

- Requires Protective Gear: Protective gloves and eyewear are recommended to prevent skin and eye irritation.

Ideal User Profile:

3M™ Rust Remover is best suited for DIYers, automotive enthusiasts, and professionals who need to remove rust from metal surfaces and prepare them for painting or coating. It’s particularly useful for those who want a less aggressive alternative to sanding or grinding.

Key Alternatives:

Alternatives include naval jelly (a similar chemical rust remover) and abrasive methods like sanding or grinding. Naval jelly is often less expensive but may be less effective on heavy rust. Sanding and grinding are more aggressive but can remove rust quickly.

Expert Overall Verdict & Recommendation:

3M™ Rust Remover is a highly recommended product for removing rust and preparing metal surfaces for painting or coating. Its effectiveness, ease of use, and minimal metal damage make it a valuable tool for various applications. While it has some limitations, such as the need for adequate ventilation and protective gear, its benefits outweigh its drawbacks. We highly recommend this product for anyone looking for a reliable and effective rust removal solution.

Insightful Q&A Section

-

Question: What is the best grit sandpaper to start with when sanding rust?

Answer: The best grit to start with depends on the severity of the rust. For light surface rust, 120-grit sandpaper may be sufficient. For more severe rust, start with 80-grit or even 60-grit sandpaper. Always move to finer grits to achieve a smooth finish. -

Question: Can I use vinegar to remove rust before sanding?

Answer: Yes, vinegar (acetic acid) is a mild acid that can dissolve rust. Soak the rusted object in vinegar for several hours or overnight, then scrub with a wire brush or sandpaper. This can loosen the rust and make sanding easier. -

Question: What is the best way to prevent rust from returning after sanding?

Answer: After sanding, thoroughly clean the metal surface to remove any residual dust or debris. Then, apply a rust-inhibiting primer and paint or coating. Regular maintenance, such as cleaning and applying protective coatings, can also help prevent rust from returning. -

Question: Is it safe to sand rust without a mask?

Answer: No, it is not safe to sand rust without a mask. Rust particles can be harmful if inhaled. Always wear a dust mask or respirator when sanding rust to protect your lungs. -

Question: What type of sandpaper is best for sanding rust?

Answer: Aluminum oxide sandpaper is a good choice for sanding rust. It is durable and effective at removing rust from metal surfaces. Silicon carbide sandpaper is another option, particularly for wet sanding. -

Question: Can I use a pressure washer to remove rust before sanding?

Answer: A pressure washer can remove loose rust and debris, making sanding easier. However, it will not remove all rust. It’s best to use a pressure washer in conjunction with other rust removal methods, such as sanding or chemical treatment. -

Question: What is the best way to clean a metal surface after sanding rust?

Answer: Use a degreaser or solvent to remove any oil, grease, or wax from the metal surface. Then, wipe the surface clean with a lint-free cloth. This will ensure that the primer and paint adhere properly. -

Question: Can I use a wire wheel on a drill to remove rust?

Answer: Yes, a wire wheel on a drill can be an effective way to remove rust. However, be careful not to apply too much pressure, as this can damage the metal surface. Always wear safety glasses when using a wire wheel. -

Question: What is the best primer to use after sanding rust?

Answer: A rust-inhibiting primer is the best choice for preventing rust from returning after sanding. Look for a primer that is specifically designed for metal surfaces and contains rust inhibitors. -

Question: How often should I inspect and maintain metal surfaces to prevent rust?

Answer: Inspect metal surfaces regularly, especially in areas that are exposed to moisture or harsh conditions. Perform maintenance as needed, such as cleaning, applying protective coatings, and repairing any damage. The frequency of inspections will depend on the environment and the type of metal.

Conclusion & Strategic Call to Action

Mastering the art of sanding rust, whether through manual methods or with the aid of chemical solutions like 3M™ Rust Remover, is essential for preserving the integrity and appearance of metal assets. We’ve explored the nuances of rust formation, the appropriate tools and techniques for removal, and the importance of preventative measures. This guide aims to arm you with the knowledge to tackle rust effectively and confidently. In our experience, a proactive approach to rust prevention is always the most cost-effective and time-saving strategy.

The future of rust prevention lies in advanced coatings and materials that offer superior corrosion resistance. As technology evolves, we can expect to see even more effective and environmentally friendly solutions for combating rust. Now that you’re equipped with this knowledge, we encourage you to share your experiences with sanding rust in the comments below. What techniques have you found most effective? What challenges have you encountered? Your insights can help others conquer rust and protect their valuable metal assets. Explore our advanced guide to rust prevention for even more in-depth information. Contact our experts for a consultation on sanding rust and tailored solutions for your specific needs.