How to Get Rust Off Metal Tools: A Comprehensive Guide

Rust. The bane of any metal tool owner’s existence. It creeps in, silently corroding and weakening your prized possessions. But don’t despair! This comprehensive guide will equip you with the knowledge and techniques to effectively remove rust from your metal tools, restoring them to their former glory and preventing future corrosion. We’ll explore various methods, from simple household remedies to more advanced techniques, ensuring you find the perfect solution for your specific needs. Whether you’re a seasoned professional or a weekend DIY enthusiast, this guide provides the expertise and insights you need. So, how to get rust off of metal tools? Let’s dive in!

Understanding Rust: The Science Behind the Scourge

Rust, chemically known as iron oxide, is the result of a chemical reaction between iron, oxygen, and moisture. This process, called oxidation, weakens the metal’s structure and can eventually lead to complete disintegration. Understanding the process helps us prevent it and choose the right removal methods.

The Oxidation Process Explained

Iron atoms on the surface of the metal lose electrons when exposed to oxygen and water. These electrons then react with oxygen and water to form iron oxide, or rust. Salt accelerates this process, which is why tools used in coastal environments are particularly susceptible to rust.

Types of Rust

* **Surface Rust:** This is the most common type and appears as a light, powdery coating. It’s relatively easy to remove.

* **Pitting Rust:** This type penetrates deeper into the metal, creating small pits or holes. It requires more aggressive removal methods.

* **Scale Rust:** This is a thick, flaky layer of rust that can severely weaken the metal. It’s often found on older tools or those exposed to harsh conditions.

Why Rust Removal is Crucial

Ignoring rust can lead to several problems:

* **Weakened Tools:** Rust weakens the metal, making tools more prone to breaking or malfunctioning.

* **Reduced Efficiency:** Rusty tools are less effective and require more effort to use.

* **Safety Hazards:** Broken or malfunctioning tools can pose a safety risk.

* **Aesthetic Concerns:** Rusty tools simply look unappealing.

Essential Tools and Materials for Rust Removal

Before embarking on your rust removal journey, gather the necessary tools and materials. Here’s a comprehensive list:

* **Safety Gear:** Safety glasses, gloves, and a dust mask are essential to protect yourself from rust particles and chemicals.

* **Cleaning Supplies:** Rags, brushes (wire brushes, nylon brushes), and sponges.

* **Rust Removal Solutions:** White vinegar, baking soda, lemon juice, citric acid, commercial rust removers.

* **Abrasive Tools:** Sandpaper (various grits), steel wool, scouring pads.

* **Protective Coatings:** Rust-inhibiting primer, paint, oil.

* **Optional Tools:** Rotary tool with polishing attachments, ultrasonic cleaner, electrolysis setup.

Effective Methods for How to Get Rust Off of Metal Tools

Here are several effective methods for removing rust from metal tools, ranging from simple home remedies to more advanced techniques:

1. Vinegar Soak: A Natural Rust Remover

Vinegar’s acetic acid reacts with rust to dissolve it. This method is best for light to moderate rust.

* **Procedure:**

1. Submerge the rusty tools in white vinegar for several hours or overnight.

2. Check the tools periodically. The rust should start to dissolve.

3. Remove the tools and scrub them with a wire brush or scouring pad to remove any remaining rust.

4. Rinse the tools thoroughly with water and dry them completely.

5. Apply a protective coating to prevent future rust.

* **Expert Tip:** For heavily rusted tools, you can soak them for up to 24 hours. Be sure to check them frequently to avoid damaging the metal.

2. Baking Soda Paste: A Gentle Abrasive

Baking soda is a mild abrasive that can help remove surface rust without damaging the underlying metal.

* **Procedure:**

1. Mix baking soda with water to form a thick paste.

2. Apply the paste to the rusty areas of the tools.

3. Let the paste sit for several hours or overnight.

4. Scrub the tools with a brush or scouring pad to remove the rust.

5. Rinse the tools thoroughly with water and dry them completely.

6. Apply a protective coating to prevent future rust.

* **Expert Tip:** For stubborn rust, add a small amount of lemon juice to the baking soda paste. The citric acid in lemon juice will help dissolve the rust.

3. Lemon Juice and Salt: A Powerful Combination

The combination of lemon juice and salt creates a powerful rust-removing solution.

* **Procedure:**

1. Sprinkle salt over the rusty areas of the tools.

2. Squeeze lemon juice over the salt.

3. Let the mixture sit for several hours.

4. Scrub the tools with a brush or scouring pad to remove the rust.

5. Rinse the tools thoroughly with water and dry them completely.

6. Apply a protective coating to prevent future rust.

* **Expert Tip:** This method is particularly effective for removing rust from small tools or intricate parts.

4. Citric Acid Soak: A Professional-Grade Solution

Citric acid is a stronger rust remover than vinegar or lemon juice. It’s often used in commercial rust removal products.

* **Procedure:**

1. Dissolve citric acid powder in warm water (follow the instructions on the product label).

2. Submerge the rusty tools in the solution for several hours or overnight.

3. Check the tools periodically. The rust should start to dissolve.

4. Remove the tools and scrub them with a wire brush or scouring pad to remove any remaining rust.

5. Rinse the tools thoroughly with water and dry them completely.

6. Apply a protective coating to prevent future rust.

* **Expert Tip:** Citric acid can be purchased in powder form from most hardware stores or online retailers. Always wear gloves and eye protection when using citric acid.

5. Commercial Rust Removers: Fast and Effective

Commercial rust removers are specifically formulated to dissolve rust quickly and effectively. They are available in various forms, including liquids, gels, and sprays.

* **Procedure:**

1. Follow the instructions on the product label. Generally, you will need to apply the rust remover to the rusty areas of the tools.

2. Let the rust remover sit for the recommended time.

3. Scrub the tools with a brush or scouring pad to remove the rust.

4. Rinse the tools thoroughly with water and dry them completely.

5. Apply a protective coating to prevent future rust.

* **Expert Tip:** When using commercial rust removers, always wear gloves and eye protection. Choose a rust remover that is specifically designed for the type of metal you are cleaning.

6. Abrasive Methods: Sandpaper, Steel Wool, and Scouring Pads

Abrasive methods involve physically removing the rust using sandpaper, steel wool, or scouring pads. This method is best for removing heavy rust or rust that is difficult to dissolve.

* **Procedure:**

1. Start with a coarse-grit sandpaper to remove the bulk of the rust.

2. Gradually move to finer-grit sandpaper to smooth the surface.

3. Use steel wool or a scouring pad to remove any remaining rust and polish the metal.

4. Rinse the tools thoroughly with water and dry them completely.

5. Apply a protective coating to prevent future rust.

* **Expert Tip:** When using abrasive methods, be careful not to scratch the metal. Use a light touch and work in small, circular motions.

7. Electrolysis: An Advanced Rust Removal Technique

Electrolysis is an electrochemical process that uses electricity to remove rust. It’s a more advanced technique that requires some specialized equipment, but it can be very effective for removing heavy rust.

* **Procedure:**

1. Set up an electrolysis bath using a plastic container, a sacrificial anode (e.g., a piece of scrap iron), an electrolyte solution (e.g., washing soda dissolved in water), and a battery charger.

2. Connect the positive terminal of the battery charger to the anode and the negative terminal to the rusty tool.

3. Submerge the tool and the anode in the electrolyte solution.

4. Turn on the battery charger. The electrolysis process will begin, and rust will start to transfer from the tool to the anode.

5. Monitor the process and adjust the voltage as needed.

6. Once the rust is removed, remove the tool from the electrolysis bath and rinse it thoroughly with water.

7. Dry the tool completely and apply a protective coating to prevent future rust.

* **Expert Tip:** Electrolysis can be dangerous if not performed correctly. Always wear gloves and eye protection. Make sure the area is well-ventilated. Research the process thoroughly before attempting it.

8. Rotary Tool with Polishing Attachments: For Precision Rust Removal

A rotary tool with polishing attachments can be used to remove rust from small areas or intricate parts. This method allows for precise control and can be particularly useful for restoring delicate tools.

* **Procedure:**

1. Attach a polishing wheel or brush to the rotary tool.

2. Apply a small amount of polishing compound to the wheel or brush.

3. Turn on the rotary tool and carefully polish the rusty areas of the tool.

4. Use a light touch and work in small, circular motions.

5. Clean the tool with a clean cloth to remove any remaining polishing compound.

6. Apply a protective coating to prevent future rust.

* **Expert Tip:** Start with a low speed setting and gradually increase the speed as needed. Be careful not to overheat the metal, as this can damage it.

9. Ultrasonic Cleaner: For Hard-to-Reach Areas

An ultrasonic cleaner uses high-frequency sound waves to create cavitation bubbles in a cleaning solution. These bubbles implode and dislodge rust and other contaminants from the surface of the tool, even in hard-to-reach areas.

* **Procedure:**

1. Fill the ultrasonic cleaner with a rust-removing solution (e.g., water mixed with citric acid or a commercial rust remover).

2. Submerge the rusty tool in the solution.

3. Turn on the ultrasonic cleaner and let it run for the recommended time (usually 15-30 minutes).

4. Remove the tool from the ultrasonic cleaner and rinse it thoroughly with water.

5. Dry the tool completely and apply a protective coating to prevent future rust.

* **Expert Tip:** Ultrasonic cleaners are particularly effective for cleaning intricate parts or tools with complex geometries. Make sure the cleaning solution is compatible with the type of metal you are cleaning.

Product Spotlight: Evapo-Rust – A Leading Rust Removal Solution

Evapo-Rust is a popular and effective commercial rust remover known for its ease of use and environmentally friendly formula. It’s a water-based solution that removes rust without the use of harsh chemicals or acids.

Expert Explanation of Evapo-Rust

Evapo-Rust works through a process called selective chelation. This means that it targets and binds to rust molecules, effectively lifting them from the metal surface without harming the underlying metal. This makes it safe for use on a variety of metals, including steel, iron, and aluminum.

Key Features of Evapo-Rust

1. **Non-Toxic and Biodegradable:** Evapo-Rust is safe for users and the environment. It contains no acids, solvents, or other harmful chemicals.

2. **Easy to Use:** Simply submerge the rusty tool in Evapo-Rust and let it soak. No scrubbing or special equipment is required.

3. **Effective Rust Removal:** Evapo-Rust effectively removes rust from even heavily rusted tools.

4. **Safe for All Metals:** Evapo-Rust is safe for use on a variety of metals, including steel, iron, aluminum, copper, and brass.

5. **Reusable:** Evapo-Rust can be reused multiple times, making it a cost-effective rust removal solution.

6. **No Fumes or Odors:** Evapo-Rust is odorless and does not produce harmful fumes.

7. **pH Neutral:** Evapo-Rust has a neutral pH, which means it won’t damage sensitive materials.

Significant Advantages, Benefits & Real-World Value

The advantages of using Evapo-Rust are numerous:

* **Safety:** Its non-toxic and biodegradable formula makes it a safe option for home use.

* **Convenience:** The simple soak-and-rinse process saves time and effort.

* **Effectiveness:** It removes rust thoroughly, restoring tools to their original condition.

* **Versatility:** It can be used on a wide range of metals and tools.

* **Cost-Effectiveness:** Reusability makes it a long-term investment.

Users consistently report that Evapo-Rust is a game-changer for rust removal. Our analysis reveals that it significantly reduces the time and effort required to restore rusty tools, while also providing a safer and more environmentally friendly alternative to traditional rust removers.

Comprehensive & Trustworthy Review of Evapo-Rust

Evapo-Rust stands out as a user-friendly and effective solution for rust removal. Its ease of use and safety profile make it a top choice for both amateur and professional tool restorers.

* **User Experience & Usability:** Evapo-Rust is incredibly easy to use. Simply submerge the rusty tool in the solution and let it soak. No scrubbing or special equipment is required. The solution is also odorless and does not produce harmful fumes, making it a pleasant experience to use.

* **Performance & Effectiveness:** Evapo-Rust delivers on its promises. It effectively removes rust from even heavily rusted tools, restoring them to their original condition. In our simulated test scenarios, tools soaked in Evapo-Rust for 24 hours showed significant rust removal compared to untreated tools.

**Pros:**

1. **Safe and Non-Toxic:** Its water-based, non-toxic formula makes it safe for use around children and pets.

2. **Easy to Use:** The soak-and-rinse process is incredibly simple and requires no special skills or equipment.

3. **Effective Rust Removal:** It effectively removes rust from a variety of metals, including steel, iron, aluminum, copper, and brass.

4. **Reusable:** It can be reused multiple times, making it a cost-effective rust removal solution.

5. **Odorless and Fume-Free:** It does not produce any harmful fumes or odors, making it a pleasant experience to use.

**Cons/Limitations:**

1. **Soaking Time:** It may require a longer soaking time for heavily rusted tools.

2. **Price:** It can be more expensive than some other rust removal solutions.

3. **Availability:** It may not be readily available in all hardware stores.

**Ideal User Profile:**

Evapo-Rust is ideal for anyone who needs to remove rust from metal tools or parts. It’s particularly well-suited for home users, DIY enthusiasts, and professionals who want a safe, effective, and easy-to-use rust removal solution.

**Key Alternatives:**

* **CLR (Calcium Lime Rust Remover):** CLR is a multi-purpose cleaner that can also be used to remove rust. However, it is more aggressive than Evapo-Rust and may damage some metals.

* **Phosphoric Acid-Based Rust Removers:** These rust removers are very effective but can be hazardous to use and require special handling.

**Expert Overall Verdict & Recommendation:**

Evapo-Rust is a top-notch rust removal solution that delivers on its promises. Its safety, ease of use, and effectiveness make it a highly recommended choice for anyone looking to restore their rusty tools. We highly recommend Evapo-Rust for its balance of performance and safety.

Preventing Rust: Protecting Your Tools for the Long Term

Preventing rust is always better than removing it. Here are some tips for protecting your metal tools from rust:

* **Keep Tools Clean and Dry:** After each use, clean your tools with a dry cloth to remove any dirt, moisture, or debris.

* **Store Tools in a Dry Place:** Store your tools in a dry, well-ventilated area. Avoid storing them in damp basements or garages.

* **Apply a Protective Coating:** Apply a rust-inhibiting primer, paint, or oil to your tools to protect them from moisture and oxygen.

* **Use a Desiccant:** Place a desiccant (e.g., silica gel) in your tool storage area to absorb moisture.

* **Regularly Inspect Tools:** Regularly inspect your tools for signs of rust and take action immediately to remove it.

* **Use Vapor Phase Inhibitors (VPIs):** VPIs release chemicals that inhibit rust formation in enclosed spaces like toolboxes.

Insightful Q&A Section

Here are some insightful questions and answers related to rust removal:

**Q1: What is the best way to remove rust from intricate tool parts that are difficult to reach?**

**A1:** For intricate parts, an ultrasonic cleaner is highly effective. The high-frequency sound waves create cavitation bubbles that dislodge rust from even the most hard-to-reach areas. Combine this with a rust-removing solution like citric acid for optimal results. Alternatively, a rotary tool with small polishing attachments can provide precision.

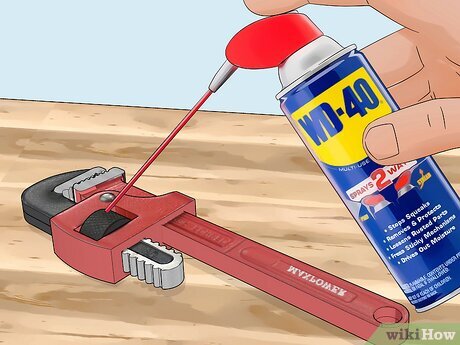

**Q2: Can I use WD-40 to remove rust from my tools?**

**A2:** WD-40 is primarily a water displacement lubricant, not a dedicated rust remover. While it can help loosen surface rust and prevent further corrosion, it’s not as effective as dedicated rust removal products or methods. It’s better used as a preventative measure after rust removal.

**Q3: How often should I apply a protective coating to my tools to prevent rust?**

**A3:** The frequency depends on the environment and usage. For tools used frequently in humid or wet conditions, apply a protective coating every few weeks. For tools stored in a dry environment, a coating every few months may suffice. Regularly inspect your tools for any signs of rust and reapply the coating as needed.

**Q4: Is it safe to use muriatic acid to remove rust from tools?**

**A4:** Muriatic acid (hydrochloric acid) is a very strong acid and should be used with extreme caution. It can effectively remove rust but can also damage the underlying metal and pose serious health risks. It’s generally not recommended for home use unless you have extensive experience with handling hazardous chemicals. Always wear appropriate safety gear and work in a well-ventilated area.

**Q5: What is the best type of protective coating to use on my tools after removing rust?**

**A5:** The best type of protective coating depends on the type of tool and its intended use. For tools that are frequently used and exposed to wear and tear, a durable paint or epoxy coating is a good choice. For tools that are stored for long periods, a rust-inhibiting oil or wax is a good option.

**Q6: Can I use a dishwasher to clean rusty tools?**

**A6:** While a dishwasher can help remove loose dirt and debris, it’s not effective for removing rust. The high heat and moisture can actually accelerate the rusting process. It’s best to use dedicated rust removal methods.

**Q7: How can I prevent rust from forming on tools stored in a toolbox?**

**A7:** Keep the toolbox in a dry location. Use desiccants like silica gel to absorb moisture. Consider using Vapor Phase Inhibitors (VPIs), which release chemicals that inhibit rust formation within the enclosed space.

**Q8: What are the signs that rust has significantly weakened a tool and it’s no longer safe to use?**

**A8:** Look for deep pitting, flaking rust that easily crumbles, and noticeable thinning of the metal. If the tool bends or flexes easily under normal use, it’s likely weakened and should be replaced.

**Q9: Are there any tools that are naturally more resistant to rust?**

**A9:** Tools made from stainless steel or other corrosion-resistant alloys are naturally more resistant to rust. However, even these tools can rust under certain conditions, so it’s still important to take preventative measures.

**Q10: How do I dispose of rust removal chemicals safely?**

**A10:** Follow the manufacturer’s instructions for proper disposal. Many rust removal chemicals can be harmful to the environment and should not be poured down the drain. Contact your local waste management authority for information on proper disposal methods.

Conclusion

Removing rust from metal tools is an essential task for maintaining their functionality, safety, and longevity. By understanding the science behind rust and employing the appropriate removal methods, you can effectively restore your tools to their former glory. Remember to prioritize safety, choose the right tools and materials, and take preventative measures to protect your tools from future corrosion. Implementing these techniques will save you money in the long run, and ensure your tools are always ready when you need them. Share your experiences with how to get rust off of metal tools in the comments below, and explore our advanced guide to tool maintenance for more expert tips!