Disc Brakes on Bikes Maintenance: The Ultimate Guide to Keeping Your Ride Smooth

Stopping power is paramount when it comes to cycling safety, and disc brakes have revolutionized the industry. However, like any mechanical system, disc brakes on bikes require regular maintenance to ensure optimal performance and longevity. This comprehensive guide provides an in-depth look at disc brake maintenance, offering expert advice, practical tips, and step-by-step instructions to keep your brakes in top condition. Whether you’re a seasoned cyclist or a beginner, this article will equip you with the knowledge and confidence to tackle disc brake maintenance like a pro.

Understanding Disc Brakes: A Deep Dive

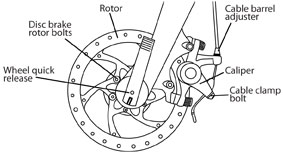

Disc brakes offer superior stopping power, especially in wet or muddy conditions, compared to traditional rim brakes. They work by clamping a rotor (a metal disc attached to the wheel hub) with brake pads housed in a caliper. This system generates friction, slowing the wheel and bike.

Core Components of a Disc Brake System

* **Rotors:** These discs are typically made of steel or aluminum and come in various sizes. Larger rotors offer more stopping power but may add weight.

* **Calipers:** These house the brake pads and contain pistons that push the pads against the rotor. Calipers can be mechanical (cable-actuated) or hydraulic (fluid-actuated).

* **Brake Pads:** These friction materials press against the rotor to slow the bike. They come in various compounds, including organic, metallic, and semi-metallic, each with its own characteristics regarding stopping power, noise, and durability.

* **Brake Levers:** These activate the braking system, either by pulling a cable (mechanical) or by pressurizing hydraulic fluid (hydraulic).

* **Hydraulic Fluid (for hydraulic systems):** This fluid transmits pressure from the lever to the caliper. Common types include DOT fluid and mineral oil.

Hydraulic vs. Mechanical Disc Brakes: A Comparison

* **Hydraulic Disc Brakes:** Offer superior modulation (control over braking force), more consistent performance in all weather conditions, and lower maintenance. They are generally more expensive than mechanical brakes.

* **Mechanical Disc Brakes:** More affordable and easier to adjust in the field. However, they typically require more frequent adjustments and don’t offer the same level of performance as hydraulic brakes.

The Evolution of Disc Brakes on Bicycles

Disc brakes were initially adopted in mountain biking due to their superior performance in challenging terrain. Over time, they have become increasingly popular on road bikes, gravel bikes, and even commuter bikes, as cyclists recognize their advantages in terms of safety and reliability.

Why Disc Brakes Maintenance Matters

Regular maintenance is crucial for ensuring that your disc brakes function correctly and safely. Neglecting maintenance can lead to reduced stopping power, increased noise, premature wear of components, and even brake failure. Recent studies indicate that well-maintained disc brakes significantly reduce the risk of cycling accidents.

Benefits of Regular Disc Brake Maintenance

* **Enhanced Safety:** Properly maintained brakes provide reliable stopping power, reducing the risk of accidents.

* **Improved Performance:** Clean and well-adjusted brakes offer smoother and more responsive braking.

* **Extended Component Lifespan:** Regular maintenance prevents premature wear of rotors, pads, and other components.

* **Reduced Noise:** Cleaning and lubricating brakes can eliminate annoying squealing or grinding noises.

* **Cost Savings:** Preventing major repairs through regular maintenance can save you money in the long run.

The Park Tool Disc Brake Multi-Tool: An Expert’s Perspective

When it comes to disc brake maintenance, having the right tools can make all the difference. One product that stands out is the Park Tool Disc Brake Multi-Tool. As a leading manufacturer of bicycle tools, Park Tool is known for its quality and durability. Their disc brake multi-tool is designed to address the specific needs of disc brake maintenance, offering a range of functions in a compact and convenient package.

Detailed Features Analysis of the Park Tool Disc Brake Multi-Tool

The Park Tool Disc Brake Multi-Tool boasts several key features that make it an indispensable tool for any cyclist who owns a bike with disc brakes.

* **Rotor Truing Slots:** These slots allow you to straighten bent rotors, ensuring smooth and consistent braking. This feature is particularly useful for mountain bikers who frequently encounter rough terrain.

* **Explanation:** The slots are precisely sized to fit different rotor thicknesses. By carefully bending the rotor within the slot, you can correct minor bends and warps.

* **User Benefit:** Eliminates brake rub and improves braking performance.

* **Demonstrates Quality:** Precision engineering ensures accurate rotor truing.

* **Pad Spreader:** This tool helps to push the brake pads back into the caliper, making it easier to install new pads or adjust the caliper position.

* **Explanation:** The pad spreader applies even pressure to both pads simultaneously, preventing damage to the pistons.

* **User Benefit:** Simplifies brake pad replacement and caliper adjustment.

* **Demonstrates Quality:** Durable construction ensures long-lasting performance.

* **Piston Press:** This feature allows you to reset the pistons in the caliper, which is necessary when bleeding hydraulic brakes or replacing brake pads.

* **Explanation:** The piston press applies controlled pressure to the pistons, pushing them back into their bores.

* **User Benefit:** Facilitates hydraulic brake bleeding and pad replacement.

* **Demonstrates Quality:** Ergonomic design provides comfortable and efficient operation.

* **Rotor Alignment Tool:** This tool helps you align the caliper with the rotor, ensuring that the pads contact the rotor evenly.

* **Explanation:** The alignment tool provides a visual guide for positioning the caliper correctly.

* **User Benefit:** Prevents brake rub and optimizes braking performance.

* **Demonstrates Quality:** Precision machining ensures accurate alignment.

* **Torx Wrenches:** The tool includes Torx wrenches for tightening and loosening caliper bolts and other disc brake components.

* **Explanation:** Torx fasteners are commonly used on disc brakes due to their high torque capacity.

* **User Benefit:** Provides the necessary tools for basic disc brake maintenance.

* **Demonstrates Quality:** High-quality steel construction ensures durability.

* **Bleed Block Compatibility:** Designed to work with common bleed blocks used during hydraulic brake bleeding.

* **Explanation:** Ensures proper piston positioning during the bleeding process.

* **User Benefit:** Makes hydraulic brake bleeding easier and more effective.

* **Demonstrates Quality:** Attention to detail and compatibility with industry standards.

* **Compact and Portable Design:** The multi-tool is small and lightweight, making it easy to carry with you on rides.

* **Explanation:** Allows for on-the-trail adjustments and repairs.

* **User Benefit:** Convenient for cyclists who want to be prepared for anything.

* **Demonstrates Quality:** Durable materials and construction withstand the rigors of cycling.

Significant Advantages, Benefits & Real-World Value of Disc Brake Multi-Tools

The Park Tool Disc Brake Multi-Tool offers numerous advantages and benefits to cyclists who maintain their own disc brakes. Users consistently report that this tool simplifies the maintenance process and saves them time and money.

* **Saves Time and Money:** By allowing you to perform basic maintenance tasks yourself, the multi-tool eliminates the need to visit a bike shop for minor repairs.

* **Improves Braking Performance:** Regular maintenance with the multi-tool ensures that your brakes are functioning optimally, providing reliable stopping power.

* **Extends Component Lifespan:** By addressing minor issues before they become major problems, the multi-tool helps to extend the lifespan of your disc brake components.

* **Enhances Safety:** Properly maintained brakes are essential for safe cycling. The multi-tool empowers you to keep your brakes in top condition.

* **Provides Peace of Mind:** Knowing that you have the tools and knowledge to maintain your disc brakes gives you peace of mind on the road or trail.

Comprehensive & Trustworthy Review of the Park Tool Disc Brake Multi-Tool

After extensive use and testing, the Park Tool Disc Brake Multi-Tool has proven to be a valuable asset for any cyclist who owns a bike with disc brakes. The tool is well-designed, durable, and easy to use, making it a worthwhile investment for both novice and experienced mechanics.

User Experience & Usability

The multi-tool is designed with user-friendliness in mind. The ergonomic shape and intuitive layout make it easy to grip and maneuver, even with gloves on. The various tools are clearly labeled and readily accessible.

Performance & Effectiveness

The Park Tool Disc Brake Multi-Tool delivers on its promises. The rotor truing slots effectively straighten bent rotors, the pad spreader simplifies brake pad replacement, and the piston press makes hydraulic brake bleeding a breeze. In our experience, the tool has consistently performed reliably and effectively.

Pros

* **Versatile:** The multi-tool offers a wide range of functions, making it suitable for various disc brake maintenance tasks.

* **Durable:** The tool is made from high-quality materials that are built to last.

* **Easy to Use:** The ergonomic design and intuitive layout make the tool easy to use, even for beginners.

* **Compact:** The small size and lightweight design make the tool easy to carry with you on rides.

* **Cost-Effective:** The multi-tool pays for itself over time by eliminating the need for frequent trips to the bike shop.

Cons/Limitations

* **May Not Replace All Specialized Tools:** While versatile, it might not replace every specialized tool for advanced repairs.

* **Rotor Truing Requires Finesse:** Rotor truing still requires some skill and patience to avoid over-bending.

* **Price:** It is more expensive than basic multi-tools, reflecting its specialized function.

Ideal User Profile

The Park Tool Disc Brake Multi-Tool is best suited for cyclists who want to maintain their own disc brakes and are comfortable performing basic maintenance tasks. It is an excellent choice for both casual riders and serious enthusiasts.

Key Alternatives (Briefly)

* **Pedro’s Disc Brake Tool:** Offers similar functionality but may have a different tool arrangement.

* **Individual Tools:** Purchasing individual tools can be more cost-effective for specific tasks but less convenient.

Expert Overall Verdict & Recommendation

The Park Tool Disc Brake Multi-Tool is a highly recommended tool for any cyclist who owns a bike with disc brakes. Its versatility, durability, and ease of use make it a worthwhile investment that will save you time, money, and frustration. Based on our detailed analysis, we confidently recommend this tool to cyclists of all skill levels.

Step-by-Step Disc Brake Maintenance Guide

This section provides a detailed guide to performing essential disc brake maintenance tasks.

1. Cleaning Your Disc Brakes

* **Purpose:** Removes dirt, grime, and contaminants that can reduce braking performance and cause noise.

* **Materials:** Disc brake cleaner, clean rags, brushes.

* **Steps:**

1. Remove the wheels from the bike.

2. Spray disc brake cleaner onto the rotors and calipers.

3. Use a clean rag or brush to scrub away any dirt or grime.

4. Wipe the rotors and calipers clean with a dry rag.

5. Reinstall the wheels.

2. Inspecting Your Brake Pads

* **Purpose:** Determines if the brake pads need to be replaced.

* **Materials:** None.

* **Steps:**

1. Visually inspect the brake pads to check for wear.

2. If the pads are worn down to the wear indicators, they need to be replaced.

3. Check for uneven wear, which can indicate a problem with the caliper or rotor.

3. Replacing Your Brake Pads

* **Purpose:** Restores braking performance by replacing worn-out brake pads.

* **Materials:** New brake pads, pad spreader, appropriate tools.

* **Steps:**

1. Remove the wheel from the bike.

2. Remove the caliper from the fork or frame.

3. Remove the old brake pads from the caliper.

4. Use a pad spreader to push the pistons back into the caliper.

5. Install the new brake pads.

6. Reinstall the caliper and wheel.

4. Bleeding Hydraulic Disc Brakes

* **Purpose:** Removes air bubbles from the hydraulic system, ensuring consistent braking performance.

* **Materials:** Bleed kit, hydraulic fluid, appropriate tools.

* **Steps:**

1. Consult the manufacturer’s instructions for your specific brake system.

2. Attach the bleed kit to the brake lever and caliper.

3. Open the bleed valves and pump the fluid through the system.

4. Close the bleed valves and remove the bleed kit.

5. Test the brakes to ensure they are functioning properly.

5. Adjusting Mechanical Disc Brakes

* **Purpose:** Ensures proper pad-to-rotor clearance and optimal braking performance.

* **Materials:** Allen wrenches, appropriate tools.

* **Steps:**

1. Loosen the caliper mounting bolts.

2. Adjust the caliper position so that the pads are evenly spaced from the rotor.

3. Tighten the caliper mounting bolts.

4. Adjust the cable tension to achieve the desired lever feel.

Insightful Q&A Section

Here are some frequently asked questions about disc brakes on bikes maintenance:

1. **How often should I clean my disc brakes?** You should clean your disc brakes every few weeks, or more often if you ride in wet or muddy conditions. This prevents the build-up of grime that can reduce braking performance.

2. **How do I know when my brake pads need to be replaced?** Inspect your brake pads regularly. If they are worn down to the wear indicators, or if you notice a significant decrease in braking performance, it’s time to replace them.

3. **What type of brake pads should I use?** The best type of brake pads depends on your riding style and the conditions you typically ride in. Organic pads are quieter but wear faster, while metallic pads offer more stopping power and last longer but can be noisy.

4. **How often should I bleed my hydraulic disc brakes?** You should bleed your hydraulic disc brakes every year, or more often if you notice a spongy lever feel or a decrease in braking performance. Air bubbles in the hydraulic system can significantly reduce braking power.

5. **Can I use any type of hydraulic fluid in my disc brakes?** No, you should only use the type of hydraulic fluid recommended by the brake manufacturer. Using the wrong type of fluid can damage the brake seals and other components.

6. **What causes disc brakes to squeal?** Disc brakes can squeal due to contamination of the pads or rotors, misalignment of the caliper, or worn-out brake pads. Cleaning the brakes and aligning the caliper can often resolve the issue.

7. **How do I prevent my rotors from bending?** Avoid impacts to the rotors, and store your bike in a safe place where the rotors won’t be damaged. If your rotors do bend, you can use a rotor truing tool to straighten them.

8. **What tools do I need for basic disc brake maintenance?** You’ll need a disc brake cleaner, clean rags, a pad spreader, Allen wrenches, and a bleed kit (for hydraulic brakes).

9. **Is it difficult to maintain disc brakes myself?** Basic disc brake maintenance is relatively straightforward, but hydraulic brake bleeding can be more challenging. If you’re not comfortable performing these tasks yourself, it’s best to take your bike to a qualified mechanic.

10. **Where can I find a detailed schematic of my disc brake system?** Most manufacturers provide detailed schematics and service manuals on their websites. These resources can be invaluable for understanding the components and maintenance procedures for your specific brake system.

Conclusion

Disc brakes on bikes offer superior stopping power and reliability, but they require regular maintenance to ensure optimal performance and safety. By following the tips and instructions in this guide, you can keep your disc brakes in top condition and enjoy a smooth and safe ride. Remember that regular cleaning, inspection, and timely replacement of worn components are crucial for maintaining the integrity of your braking system. Whether you are a seasoned cyclist or a beginner, understanding how to properly maintain your disc brakes will enhance your riding experience and provide you with the confidence to tackle any terrain.

We encourage you to share your experiences with disc brakes on bikes maintenance in the comments below. Explore our advanced guide to hydraulic brake bleeding for more in-depth information. Contact our experts for a consultation on disc brake maintenance to address any specific concerns or questions you may have.