Cut Brake Cable Bike? Expert Guide to Repair & Replacement

Discovering a cut brake cable on your bike can be a frustrating and potentially dangerous situation. Whether you’re a seasoned cyclist or a casual rider, understanding how to address this issue is crucial for your safety and the longevity of your bicycle. This comprehensive guide provides expert insights, step-by-step instructions, and essential tips for repairing or replacing a cut brake cable bike, ensuring you get back on the road with confidence. We aim to provide a resource that goes beyond basic instructions, offering a deep dive into the mechanics, troubleshooting, and preventative measures related to cut brake cable bike issues.

This article will equip you with the knowledge to diagnose the problem, select the right replacement parts, and perform the necessary repairs. We’ll also explore common causes of cable damage, preventative maintenance strategies, and when it’s best to consult a professional. Our goal is to empower you to handle this common bike repair with expertise and confidence, extending the life of your bike and ensuring your safety on every ride.

Understanding Cut Brake Cables: Causes and Consequences

A cut brake cable on your bike is more than just an inconvenience; it’s a safety hazard that requires immediate attention. Before diving into the repair process, it’s essential to understand the common causes of cable damage and the potential consequences of riding with compromised brakes.

Common Causes of Cut Brake Cables

- Fraying and Wear: Over time, brake cables can fray due to friction and repeated use. These frayed strands can weaken the cable, making it more susceptible to snapping or being cut.

- Improper Installation: Incorrect cable routing or improper tension can put undue stress on the cable, leading to premature wear and potential cuts.

- Corrosion and Rust: Exposure to moisture and harsh weather conditions can cause corrosion and rust to form on the cable, weakening its structural integrity.

- Accidental Damage: Impacts from crashes, falls, or even sharp objects can directly cut or damage the cable housing, exposing the inner cable to further damage.

- Poor Quality Cables: Using low-quality or incompatible cables can result in them failing under normal braking conditions.

Consequences of Riding with a Cut Brake Cable

Riding with a cut or damaged brake cable significantly compromises your ability to stop quickly and safely. This can lead to:

- Increased Stopping Distance: Reduced braking power means you’ll need more distance to come to a complete stop, increasing the risk of collisions.

- Loss of Control: In emergency situations, the inability to brake effectively can result in a loss of control, potentially leading to accidents and injuries.

- Further Damage: Attempting to ride with a damaged cable can cause further damage to the brake system, potentially requiring more extensive repairs.

Therefore, addressing a cut brake cable bike issue promptly is not just about convenience; it’s about ensuring your safety and preventing more significant problems down the line.

Essential Tools and Materials for Brake Cable Repair

Before you can begin the process of repairing or replacing a cut brake cable bike, you’ll need to gather the necessary tools and materials. Having everything on hand will streamline the process and ensure you can complete the repair efficiently and effectively.

Tools You’ll Need

- Cable Cutters: These specialized cutters provide a clean and precise cut, preventing fraying and ensuring a smooth cable end.

- Allen Wrench Set: Metric Allen wrenches are essential for loosening and tightening various bolts and screws on the brake levers and calipers.

- Pliers: Standard pliers can be useful for gripping and manipulating the cable during installation.

- Screwdrivers: A set of Phillips and flathead screwdrivers may be needed for adjusting brake components.

- Cable Housing Cutters (Optional): If you need to replace the cable housing, these cutters provide a clean, square cut.

- Brake Cable Crimps: These small metal caps prevent the cable from fraying after it’s been cut.

Materials You’ll Need

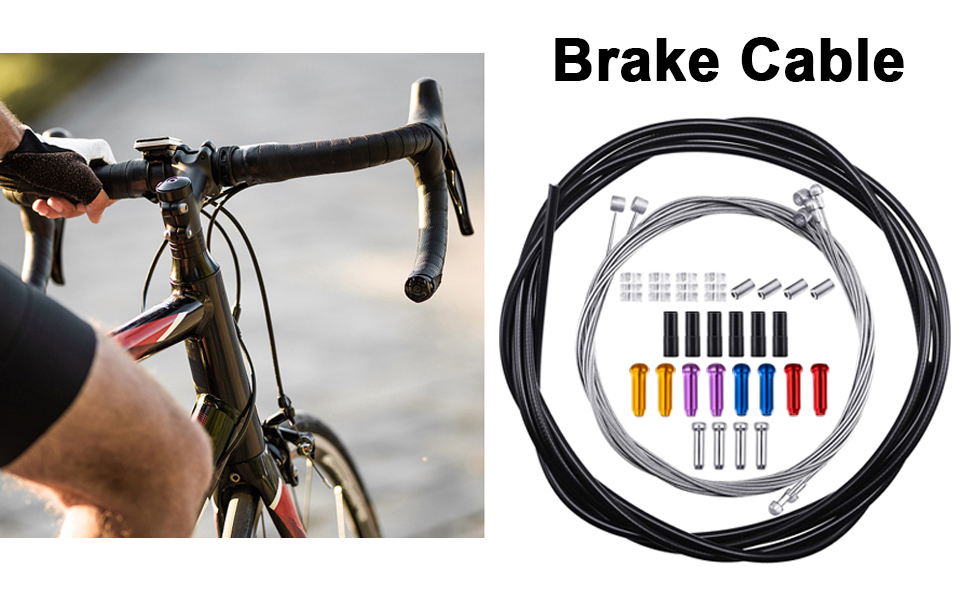

- Replacement Brake Cable: Choose a high-quality brake cable that is compatible with your bike’s brake system (e.g., road bike or mountain bike).

- Replacement Cable Housing (Optional): If the cable housing is damaged or corroded, replace it along with the cable.

- Cable End Caps: These small caps prevent dirt and debris from entering the cable housing.

- Brake Cleaner: Use brake cleaner to remove dirt and grime from the brake components.

- Lubricant: Apply a small amount of lubricant to the cable before installation to reduce friction and improve performance.

Investing in quality tools and materials will not only make the repair process easier but also ensure the longevity and reliability of your brake system. Neglecting to use the right tools can lead to further damage or improper installation, compromising your safety.

Step-by-Step Guide to Replacing a Cut Brake Cable

Replacing a cut brake cable bike can seem daunting, but by following a step-by-step guide, you can confidently tackle this repair. This section provides a detailed walkthrough of the replacement process, ensuring you understand each step and can perform the repair safely and effectively.

Step 1: Remove the Old Brake Cable

- Loosen the Brake Caliper Bolt: Use an Allen wrench to loosen the bolt that secures the brake cable to the brake caliper.

- Disconnect the Cable: Carefully disconnect the cable from the caliper, noting the cable routing for reinstallation.

- Remove the Cable from the Lever: Squeeze the brake lever and disengage the cable from the lever mechanism.

- Pull the Cable Out: Gently pull the old cable out of the housing, starting from the lever end.

Step 2: Prepare the New Brake Cable

- Inspect the New Cable: Check the new cable for any damage or defects before installation.

- Apply Lubricant: Apply a small amount of lubricant to the cable to reduce friction and improve performance.

Step 3: Install the New Brake Cable

- Insert the Cable into the Housing: Starting from the lever end, carefully insert the new cable into the housing, ensuring it runs smoothly through the entire length.

- Connect the Cable to the Lever: Squeeze the brake lever and engage the cable into the lever mechanism.

- Connect the Cable to the Caliper: Route the cable to the brake caliper and secure it with the bolt, ensuring proper tension.

- Adjust the Brake Tension: Fine-tune the brake tension by adjusting the barrel adjuster on the brake lever or caliper.

Step 4: Test and Adjust the Brakes

- Test the Brakes: Squeeze the brake levers firmly to ensure the brakes engage properly and provide sufficient stopping power.

- Adjust as Needed: If the brakes feel too loose or too tight, adjust the cable tension accordingly.

- Secure the Cable End: Use a cable crimp to secure the end of the cable, preventing fraying.

By following these steps carefully, you can successfully replace a cut brake cable bike and restore your bike’s braking performance. Remember to always prioritize safety and double-check your work before riding.

Troubleshooting Common Brake Cable Issues

Even with careful installation, you may encounter issues when replacing a cut brake cable bike. This section addresses common problems and provides troubleshooting tips to help you resolve them effectively.

Issue 1: Brakes Feel Loose or Spongy

- Possible Causes: Cable stretch, air in the brake lines (for hydraulic brakes), improper cable tension.

- Troubleshooting Steps: Adjust the cable tension using the barrel adjuster. Bleed the brake lines if you have hydraulic brakes. Check for any leaks in the brake system.

Issue 2: Brakes Feel Too Tight or Grab

- Possible Causes: Over-tightened cable, sticking brake calipers, contaminated brake pads.

- Troubleshooting Steps: Loosen the cable tension. Clean and lubricate the brake calipers. Replace the brake pads if they are contaminated.

Issue 3: Cable Fraying or Snapping

- Possible Causes: Poor quality cable, improper installation, excessive friction.

- Troubleshooting Steps: Replace the cable with a high-quality one. Ensure proper cable routing and lubrication. Check for any sharp edges or obstructions that may be causing friction.

Issue 4: Brake Levers Feel Stiff or Difficult to Pull

- Possible Causes: Corroded cable, damaged cable housing, lack of lubrication.

- Troubleshooting Steps: Replace the cable and housing. Apply lubricant to the cable and housing. Check for any kinks or bends in the cable routing.

By understanding these common issues and their solutions, you can effectively troubleshoot brake cable problems and maintain your bike’s braking performance.

Preventative Maintenance for Brake Cables

Preventing brake cable issues is always better than dealing with a cut brake cable bike. Regular maintenance can significantly extend the life of your brake cables and ensure your safety on the road. This section outlines essential preventative maintenance practices.

Regular Cleaning and Lubrication

Dirt, grime, and moisture can accelerate wear and corrosion on brake cables. Regularly cleaning and lubricating the cables can help prevent these issues.

- Cleaning: Use a clean cloth to wipe down the brake cables and housing, removing any dirt or debris.

- Lubrication: Apply a small amount of bicycle-specific lubricant to the cable, ensuring it penetrates the housing.

Inspecting for Wear and Damage

Regularly inspect your brake cables for signs of wear, fraying, or damage. Early detection can prevent cable failure and potential accidents.

- Visual Inspection: Check the cable for any visible signs of fraying, rust, or kinks.

- Functional Inspection: Squeeze the brake levers and check for smooth and consistent operation.

Proper Cable Routing and Tension

Ensure that the brake cables are properly routed and have the correct tension. Improper routing or tension can put undue stress on the cable, leading to premature wear.

- Cable Routing: Ensure the cables are routed smoothly and without any sharp bends or kinks.

- Cable Tension: Adjust the cable tension to ensure the brakes engage properly without being too tight or too loose.

Replacing Cables Regularly

Even with proper maintenance, brake cables will eventually wear out and need to be replaced. Replacing them regularly can prevent unexpected failures.

- Recommended Replacement Interval: Replace brake cables every 1-2 years, depending on usage and riding conditions.

By following these preventative maintenance practices, you can significantly reduce the risk of a cut brake cable bike and ensure your safety on every ride.

Choosing the Right Replacement Brake Cable

Selecting the right replacement brake cable is crucial for ensuring proper braking performance and safety. This section provides guidance on choosing the appropriate cable for your bike.

Cable Type

Brake cables come in different types, each designed for specific brake systems. The two main types are:

- Road Bike Cables: These cables have a pear-shaped end that fits into road bike brake levers.

- Mountain Bike Cables: These cables have a mushroom-shaped end that fits into mountain bike brake levers.

Ensure you choose the correct cable type for your bike’s brake system.

Cable Material

Brake cables are typically made from steel or stainless steel. Stainless steel cables offer better corrosion resistance and durability.

- Steel Cables: These are more affordable but may be more susceptible to corrosion.

- Stainless Steel Cables: These offer better corrosion resistance and longer lifespan.

Cable Diameter

Brake cables come in different diameters. Ensure you choose a cable diameter that is compatible with your brake levers and calipers.

- Standard Diameter: Most brake systems use a standard cable diameter.

Cable Length

Choose a cable length that is long enough to reach from the brake lever to the caliper without being too short or too long.

- Measure the Old Cable: Use the old cable as a guide to determine the correct length.

By considering these factors, you can choose the right replacement brake cable and ensure optimal braking performance.

When to Consult a Professional Mechanic

While replacing a cut brake cable bike can be a DIY project, there are situations where it’s best to consult a professional mechanic. This section outlines scenarios where professional assistance is recommended.

Complex Brake Systems

If your bike has a complex brake system, such as hydraulic disc brakes, it’s best to consult a professional mechanic. Hydraulic brakes require specialized tools and knowledge to service properly.

Unfamiliarity with Brake Systems

If you are not familiar with brake systems or have limited mechanical experience, it’s best to seek professional assistance. Improper installation or adjustment can compromise your safety.

Persistent Brake Problems

If you encounter persistent brake problems, such as brake squeal, poor braking performance, or leaks, it’s best to consult a professional mechanic. These issues may indicate underlying problems that require expert diagnosis and repair.

Lack of Proper Tools

If you lack the proper tools to perform the repair, it’s best to consult a professional mechanic. Using the wrong tools can damage the brake system and compromise your safety.

Consulting a professional mechanic can ensure that the repair is done correctly and safely, giving you peace of mind and ensuring your bike’s braking performance.

Expert Q&A: Cut Brake Cable Bike

Here are some frequently asked questions about dealing with a cut brake cable bike, answered by our expert mechanics:

-

Q: How often should I replace my brake cables, even if they aren’t cut?

A: As a general rule, replace your brake cables every 1-2 years, or more frequently if you ride in harsh conditions or notice signs of wear. Regular replacement prevents unexpected failures.

-

Q: Can I use any type of cable housing for my brakes?

A: No, it’s crucial to use cable housing specifically designed for brakes. Using derailleur housing can lead to brake failure due to its compressibility.

-

Q: What’s the best way to prevent cable fraying?

A: Always use sharp cable cutters for a clean cut, and immediately install a cable end crimp. Regular lubrication also helps prevent fraying.

-

Q: Are hydraulic brakes more reliable than cable brakes?

A: Hydraulic brakes offer more consistent performance and require less maintenance, but they are more complex to repair. Cable brakes are simpler and easier to adjust.

-

Q: Can I mix and match brake levers and calipers from different brands?

A: It’s generally not recommended, as compatibility issues can arise. Stick to components from the same brand or ensure they are specifically designed to work together.

-

Q: What does it mean when my brakes squeal?

A: Brake squeal can be caused by contaminated brake pads, misaligned calipers, or worn rotors. Cleaning or replacing the pads and adjusting the calipers often resolves the issue.

-

Q: How do I know if my brake pads need replacing?

A: Check the thickness of the brake pads. If they are worn down to 1-2mm, it’s time to replace them. Also, replace them if they are contaminated with oil or grease.

-

Q: Is it normal for new brake cables to stretch after installation?

A: Yes, it’s normal for new cables to stretch slightly after installation. Re-adjust the cable tension after a few rides to compensate for the stretch.

-

Q: What type of lubricant is best for brake cables?

A: Use a bicycle-specific dry lubricant. Avoid using oil-based lubricants, as they can attract dirt and grime.

-

Q: Should I replace the cable housing when I replace the cable?

A: It’s highly recommended to replace the cable housing along with the cable, especially if the housing is old, damaged, or corroded. This ensures smooth cable movement and optimal braking performance.

Conclusion

Dealing with a cut brake cable bike can be a manageable task with the right knowledge, tools, and approach. By understanding the causes of cable damage, following our step-by-step repair guide, and implementing preventative maintenance practices, you can keep your bike’s braking system in top condition. Prioritizing safety and addressing brake cable issues promptly will ensure a safer and more enjoyable riding experience. Remember, if you’re ever unsure or uncomfortable with the repair process, consulting a professional mechanic is always the best option. Our goal is to empower you with the expertise to handle common bike repairs and maintain your bike’s performance.

Now that you’re equipped with the knowledge to handle a cut brake cable bike, share your experiences in the comments below! Do you have any additional tips or tricks for brake cable maintenance? Let’s build a community of knowledgeable cyclists who prioritize safety and bike maintenance.