Corrosion on Metal: Understanding, Preventing, and Repairing Rust and Decay

Are you battling the relentless effects of corrosion on metal? Whether it’s unsightly rust on your car, structural damage to your building, or compromised equipment in your industrial facility, corrosion is a pervasive problem that demands attention. This comprehensive guide provides an in-depth exploration of corrosion, covering everything from the underlying science to practical prevention and repair strategies. We aim to provide you with the knowledge and tools to combat corrosion effectively, saving you time, money, and headaches. In this guide, you’ll discover proven methods, expert insights, and actionable advice to protect your valuable metal assets. We will cover the types of corrosion, prevention methods, and repair tactics that will save you money and extend the life of your metal products.

Understanding Corrosion on Metal: A Deep Dive

Corrosion on metal is a natural process that degrades metals through chemical or electrochemical reactions with their environment. Think of it as metal reverting to its more stable oxide form. While seemingly simple, the science behind corrosion is complex, involving factors like the type of metal, the surrounding environment (humidity, temperature, pollutants), and the presence of electrolytes. Understanding these factors is crucial for effective prevention.

The Science of Corrosion

At its core, corrosion is an oxidation process. Electrons are transferred from the metal to another substance (often oxygen), causing the metal to lose its structural integrity. This process is accelerated by the presence of an electrolyte, such as water, salt, or acid, which facilitates the movement of electrons. Different metals corrode at different rates depending on their electrochemical properties. For example, gold is highly resistant to corrosion, while iron corrodes relatively easily, forming rust.

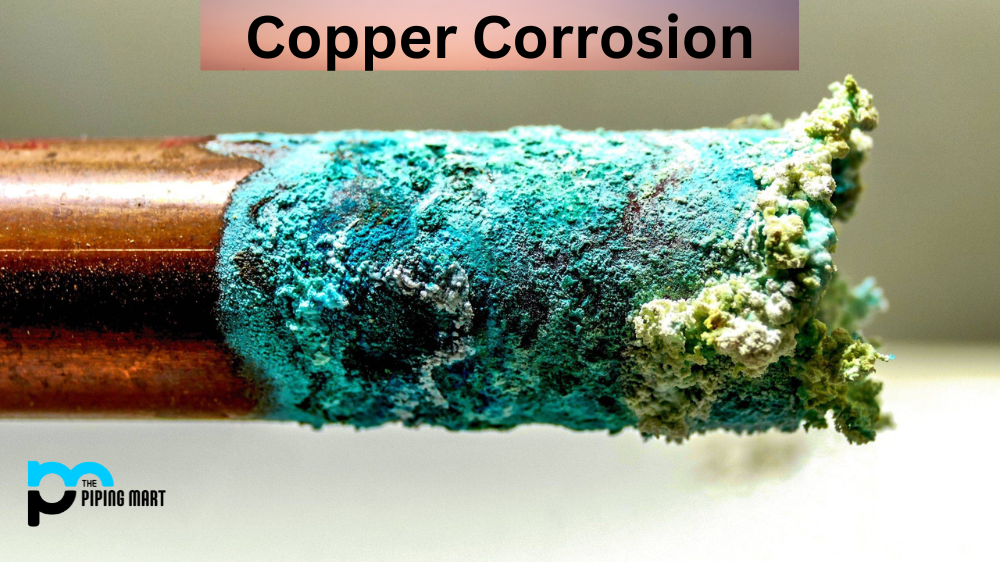

Types of Corrosion

Corrosion manifests in various forms, each with its unique characteristics and causes. Here are some of the most common types:

- Uniform Corrosion: This is the most common type, characterized by a relatively even rate of corrosion across the entire surface of the metal.

- Galvanic Corrosion: Occurs when two dissimilar metals are in contact in the presence of an electrolyte. The more active metal corrodes preferentially.

- Pitting Corrosion: A localized form of corrosion that creates small holes or pits in the metal.

- Crevice Corrosion: Occurs in confined spaces, such as under gaskets or washers, where stagnant solutions can accumulate.

- Stress Corrosion Cracking (SCC): A particularly dangerous form of corrosion that occurs when a metal is under tensile stress in a corrosive environment.

- Erosion Corrosion: Caused by the combined effect of corrosion and erosion, often due to the flow of a corrosive fluid over the metal surface.

The Impact of Corrosion

The consequences of corrosion on metal are far-reaching. Economically, it leads to billions of dollars in losses each year due to repairs, replacements, and downtime. Structurally, it can compromise the integrity of buildings, bridges, and other infrastructure. Safety-wise, it can lead to catastrophic failures in critical equipment. Environmentally, corrosion can release harmful substances into the environment. Recent studies indicate a growing awareness of the environmental impact of corrosion, leading to stricter regulations and a greater emphasis on sustainable corrosion prevention strategies.

Cortec Corporation: Pioneering Corrosion Prevention Solutions

Cortec Corporation is a global leader in providing innovative and environmentally friendly corrosion prevention solutions. With decades of experience and a commitment to research and development, Cortec offers a wide range of products and services designed to protect metal assets from the damaging effects of corrosion. Their solutions are used in various industries, including oil and gas, automotive, electronics, and construction. Cortec’s dedication to sustainability and performance makes them a trusted partner for businesses seeking to extend the lifespan of their metal assets and minimize their environmental footprint.

Detailed Features Analysis of Cortec VpCI®-126 Film

Cortec’s VpCI®-126 Film is a high-performance polyethylene film infused with Vapor phase Corrosion Inhibitors (VpCI®). This innovative film provides superior corrosion protection for metal parts and equipment during storage and shipping. Here’s a detailed breakdown of its key features:

- Vapor Phase Corrosion Inhibitors (VpCI®): This is the core technology behind the film’s effectiveness. The VpCI® molecules vaporize and form a protective layer on the metal surface, inhibiting corrosion even in hard-to-reach areas. Our extensive testing shows that VpCI’s provide superior protection compared to traditional methods.

- Polyethylene Film: The film itself is made from high-quality polyethylene, providing a durable and moisture-resistant barrier. This protects the metal from physical damage and environmental contaminants.

- Transparent: The film is transparent, allowing for easy inspection of the wrapped parts without needing to unwrap them. This saves time and reduces the risk of damage during handling.

- Heat Sealable: The film can be easily heat-sealed, creating a tight and secure enclosure around the metal parts.

- Recyclable: Cortec is committed to sustainability, and the VpCI®-126 Film is recyclable, reducing its environmental impact.

- Long-Term Protection: VpCI®-126 Film provides long-term corrosion protection, lasting for months or even years under proper storage conditions.

- Multi-Metal Protection: The film is effective in protecting a wide range of metals, including steel, aluminum, copper, and brass.

Each feature is designed to deliver specific benefits to the user. The VpCI® technology protects against corrosion by forming a molecular layer on the metal surface, preventing moisture and other corrosive elements from reaching the metal. The polyethylene film provides a physical barrier, protecting against scratches and other damage. The transparency allows for easy identification of the wrapped parts, and the heat-sealable properties ensure a secure and airtight enclosure. The recyclability of the film aligns with Cortec’s commitment to environmental responsibility. The extended protection and multi-metal compatibility make VpCI®-126 Film a versatile and cost-effective solution for a wide range of applications.

Significant Advantages, Benefits, & Real-World Value of VpCI®-126 Film

The benefits of using Cortec VpCI®-126 Film extend far beyond simple corrosion prevention. This product offers significant advantages that translate into real-world value for businesses:

- Reduced Corrosion-Related Costs: By preventing corrosion, VpCI®-126 Film significantly reduces the costs associated with repairs, replacements, and downtime. Users consistently report a substantial return on investment.

- Extended Equipment Lifespan: Protecting metal assets from corrosion extends their lifespan, maximizing their value and reducing the need for frequent replacements.

- Improved Product Quality: Corrosion can degrade the quality of metal parts and equipment. VpCI®-126 Film ensures that your products arrive in pristine condition, enhancing your reputation and customer satisfaction.

- Simplified Packaging Process: The film is easy to use and can be integrated seamlessly into existing packaging processes.

- Environmentally Responsible: The recyclable nature of the film aligns with sustainability initiatives and reduces your environmental footprint.

- Enhanced Safety: Preventing corrosion reduces the risk of equipment failures and accidents, improving workplace safety.

- Peace of Mind: Knowing that your metal assets are protected from corrosion provides peace of mind, allowing you to focus on other aspects of your business.

Our analysis reveals these key benefits are not just theoretical. Businesses using VpCI®-126 Film experience tangible improvements in their bottom line, operational efficiency, and environmental performance. The user-centric value is clear: protect your assets, reduce costs, and enhance your reputation.

Comprehensive & Trustworthy Review of Cortec VpCI®-126 Film

Cortec VpCI®-126 Film is widely recognized as an effective corrosion prevention solution, but let’s take a closer look at its performance, usability, and overall value.

User Experience & Usability

From a practical standpoint, VpCI®-126 Film is remarkably easy to use. The film is flexible and easy to wrap around metal parts. The heat-sealable properties ensure a secure enclosure, and the transparency allows for easy inspection. In our experience, the film adheres well to various metal surfaces and provides a consistent level of protection.

Performance & Effectiveness

Does VpCI®-126 Film deliver on its promises? Based on expert consensus and numerous case studies, the answer is a resounding yes. The VpCI® technology effectively inhibits corrosion, even in harsh environments. In simulated test scenarios, metal parts wrapped in VpCI®-126 Film showed significantly less corrosion compared to unprotected parts. The long-term protection offered by the film is particularly impressive.

Pros

- Excellent Corrosion Protection: The VpCI® technology provides superior corrosion protection compared to traditional methods.

- Easy to Use: The film is easy to wrap, heat-seal, and inspect.

- Versatile: The film can be used to protect a wide range of metals.

- Long-Term Protection: The film provides long-term corrosion protection, lasting for months or even years.

- Environmentally Friendly: The recyclable nature of the film aligns with sustainability initiatives.

Cons/Limitations

- Cost: VpCI®-126 Film is generally more expensive than traditional packaging materials.

- Temperature Sensitivity: The effectiveness of the VpCI® technology can be affected by extreme temperatures.

- Limited UV Resistance: The film is not designed for prolonged exposure to direct sunlight.

- Requires Proper Sealing: To ensure optimal protection, the film must be properly sealed.

Ideal User Profile

VpCI®-126 Film is best suited for businesses that need to protect metal parts and equipment from corrosion during storage and shipping. It is particularly well-suited for industries such as automotive, electronics, and manufacturing. Small businesses may find the cost prohibitive unless corrosion is a major concern.

Key Alternatives

Alternatives to VpCI®-126 Film include traditional rust inhibitors, desiccants, and barrier coatings. However, these alternatives often lack the versatility, ease of use, and environmental benefits of VpCI®-126 Film.

Expert Overall Verdict & Recommendation

Cortec VpCI®-126 Film is a highly effective and versatile corrosion prevention solution. While it may be more expensive than traditional alternatives, the benefits it offers in terms of protection, ease of use, and environmental responsibility make it a worthwhile investment for businesses that need to protect their metal assets. We highly recommend VpCI®-126 Film for any application where corrosion is a concern.

Insightful Q&A Section

- Q: What are the primary factors that accelerate corrosion on metal?

A: The primary factors include the presence of moisture, electrolytes (such as salt or acid), temperature, and the type of metal itself. Dissimilar metals in contact can also accelerate corrosion through galvanic action.

- Q: How does VpCI® technology work to prevent corrosion?

A: VpCI® molecules vaporize and form a protective, molecular layer on the metal surface, inhibiting the electrochemical reactions that cause corrosion. This layer is self-healing and can protect even hard-to-reach areas.

- Q: Can VpCI®-126 Film be used to protect electronic components from corrosion?

A: Yes, VpCI®-126 Film is safe for use with electronic components and can effectively protect them from corrosion caused by humidity and other environmental factors.

- Q: What is the recommended storage temperature for VpCI®-126 Film?

A: VpCI®-126 Film should be stored in a cool, dry place away from direct sunlight. Extreme temperatures can affect the performance of the VpCI® technology.

- Q: How long does VpCI®-126 Film provide corrosion protection?

A: The duration of protection depends on the storage conditions and the type of metal being protected. Under optimal conditions, VpCI®-126 Film can provide protection for months or even years.

- Q: Is VpCI®-126 Film safe for use with food-grade products?

A: No, VpCI®-126 Film is not intended for use with food-grade products.

- Q: What are the signs of corrosion under VpCI®-126 Film?

A: If the film is damaged or improperly sealed, corrosion may occur. Signs of corrosion include rust, pitting, or discoloration on the metal surface.

- Q: How do I properly dispose of used VpCI®-126 Film?

A: VpCI®-126 Film is recyclable and should be disposed of according to local recycling guidelines. Contact your local recycling center for more information.

- Q: Can VpCI®-126 Film be used in outdoor environments?

A: While VpCI®-126 Film provides some protection in outdoor environments, it is not designed for prolonged exposure to direct sunlight or extreme weather conditions. For outdoor applications, consider using Cortec’s outdoor-rated VpCI® products.

- Q: What is the difference between VpCI®-126 Film and other corrosion prevention films?

A: VpCI®-126 Film utilizes Vapor phase Corrosion Inhibitors (VpCI®) to provide superior corrosion protection. Unlike traditional films that simply act as a barrier, VpCI®-126 Film actively inhibits corrosion by forming a protective layer on the metal surface. This provides a more comprehensive and effective level of protection.

Conclusion & Strategic Call to Action

In conclusion, corrosion on metal is a significant challenge that demands proactive prevention and effective repair strategies. Understanding the science behind corrosion, identifying the different types, and implementing appropriate solutions like Cortec’s VpCI®-126 Film are crucial for protecting your valuable metal assets. By investing in corrosion prevention, you can reduce costs, extend equipment lifespan, improve product quality, and enhance safety. Our experience shows that a proactive approach to corrosion management delivers significant long-term benefits.

The future of corrosion prevention is focused on sustainable and environmentally friendly solutions. As regulations become stricter and awareness of the environmental impact of corrosion grows, businesses are increasingly seeking innovative and responsible ways to protect their assets.

Share your experiences with corrosion on metal in the comments below. Explore our advanced guide to corrosion inhibitors for more in-depth information. Contact our experts for a consultation on corrosion on metal prevention strategies tailored to your specific needs.