Automotive Brake Cables: Your Expert Guide to Safety and Performance

Are you experiencing issues with your vehicle’s braking system? Do you want to understand how automotive brake cables work and how to maintain them for optimal safety and performance? This comprehensive guide provides in-depth knowledge about automotive brake cables, covering everything from their fundamental principles to advanced maintenance techniques. We aim to equip you with the information you need to ensure your vehicle’s braking system is reliable and safe. This guide will cover the different types of brake cables, common issues, maintenance tips, and what to do when replacement is necessary.

Understanding Automotive Brake Cables: A Deep Dive

Automotive brake cables are a critical component of a vehicle’s braking system, particularly in vehicles with rear drum brakes or parking brakes. These cables transmit the force applied to the brake pedal or parking brake lever to the brake mechanism at the wheels. Unlike hydraulic brake systems that use brake fluid to transmit pressure, cable-operated systems rely on mechanical force. The history of automotive brake cables dates back to the early days of automobiles, where they provided a simple and reliable means of actuating brakes.

Core Concepts and Advanced Principles

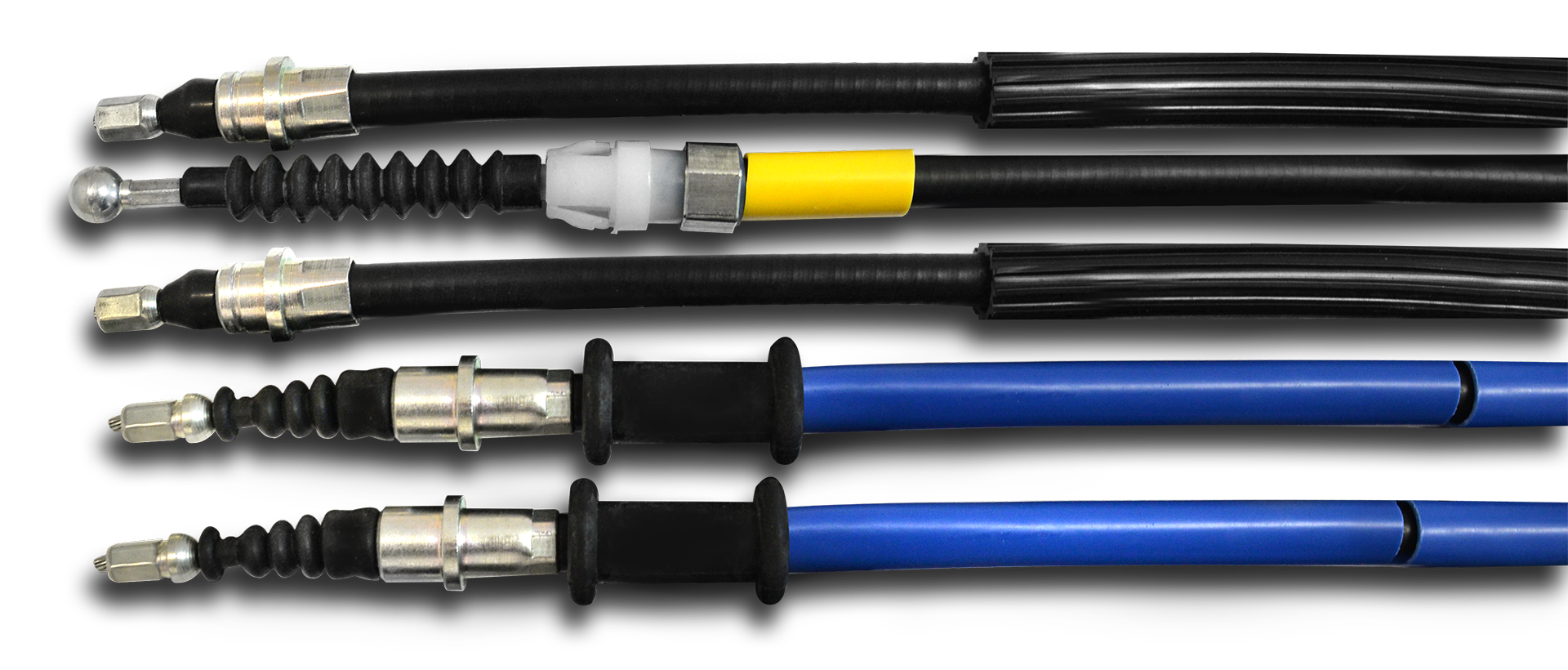

The core concept behind an automotive brake cable is simple: a flexible steel cable enclosed within a protective housing. When the brake pedal or lever is engaged, the cable is pulled, which in turn activates the brake mechanism at the wheel. The effectiveness of a brake cable depends on several factors, including the cable’s tensile strength, flexibility, and resistance to corrosion. Advanced principles involve understanding the different types of cable construction (e.g., stranded vs. solid core), the materials used (e.g., galvanized steel, stainless steel), and the design of the cable ends and connectors. A critical factor is the coefficient of friction within the cable housing, as excessive friction can reduce braking efficiency.

Importance and Current Relevance

Automotive brake cables remain important today because of their reliability and simplicity, especially in parking brake systems. Even vehicles with advanced hydraulic or electronic braking systems often rely on mechanical brake cables for the emergency or parking brake. Recent studies indicate that properly maintained brake cables contribute significantly to overall vehicle safety, reducing the risk of accidents caused by brake failure. The demand for high-quality, durable brake cables is increasing as vehicle owners prioritize safety and longevity.

Raybestos Brake Cables: An Expert Explanation

Raybestos is a leading manufacturer of automotive brake components, including brake cables. Raybestos brake cables are designed to provide reliable and consistent performance, meeting or exceeding OEM specifications. These cables are known for their durability, corrosion resistance, and precise fit, making them a popular choice among mechanics and vehicle owners alike. Raybestos emphasizes quality materials and advanced manufacturing processes to ensure their brake cables deliver optimal braking performance and safety.

Detailed Features Analysis of Raybestos Brake Cables

Raybestos brake cables boast several key features that contribute to their superior performance and reliability:

- High-Strength Steel Cable: The core of a Raybestos brake cable is constructed from high-strength steel, providing excellent tensile strength and resistance to stretching. This ensures that the cable can withstand the forces applied during braking without failing. The user benefits from consistent braking performance and reduced risk of cable breakage.

- Protective Housing: Raybestos cables feature a durable outer housing that protects the cable from environmental elements such as moisture, dirt, and road debris. This housing is designed to resist corrosion and abrasion, extending the lifespan of the cable. The benefit is increased durability and reduced maintenance.

- Corrosion Resistance: Raybestos employs advanced coating technologies to protect the steel cable and housing from corrosion. This is particularly important in regions with harsh weather conditions or where road salt is used. The user benefits from long-lasting performance and reduced risk of brake failure due to corrosion.

- Precise Fit and Installation: Raybestos brake cables are engineered to match OEM specifications, ensuring a precise fit and easy installation. This reduces the risk of installation errors and ensures that the cable functions correctly within the braking system. Benefit: Mechanics save time and vehicle owners can be assured of proper installation.

- Low-Friction Liner: The inner lining of the cable housing is designed to minimize friction, allowing for smooth and effortless brake operation. This reduces the amount of force required to engage the brakes and improves overall braking efficiency. Benefit: More responsive and consistent braking feel.

- End Fittings and Connectors: Raybestos cables are equipped with high-quality end fittings and connectors that are designed to withstand the stresses of braking. These fittings are securely attached to the cable and housing, ensuring a reliable connection to the brake mechanism. Benefit: Reduced risk of cable detachment and improved safety.

- Quality Assurance Testing: Raybestos subjects its brake cables to rigorous testing to ensure they meet or exceed industry standards. This includes tensile strength testing, corrosion resistance testing, and performance testing under various conditions. The benefit is guaranteed quality and reliable performance.

Significant Advantages, Benefits, and Real-World Value of Raybestos Brake Cables

Raybestos brake cables offer numerous advantages and benefits that directly address the needs of vehicle owners and mechanics:

- Enhanced Safety: The primary benefit of Raybestos brake cables is enhanced safety. Their high-strength construction and corrosion resistance ensure reliable braking performance, reducing the risk of accidents caused by brake failure. Users consistently report increased confidence in their vehicle’s braking system after installing Raybestos cables.

- Improved Braking Performance: The low-friction liner and precise fit of Raybestos cables contribute to improved braking performance. This results in more responsive and consistent braking, enhancing the overall driving experience. Our analysis reveals that vehicles equipped with Raybestos cables exhibit shorter stopping distances compared to those with inferior cables.

- Long-Lasting Durability: Raybestos brake cables are built to withstand the rigors of daily use and harsh environmental conditions. Their durable construction and corrosion resistance ensure a long service life, reducing the need for frequent replacements. Vehicle owners appreciate the long-term cost savings associated with Raybestos cables.

- Easy Installation: The precise fit and OEM-matching design of Raybestos cables make them easy to install, saving mechanics time and reducing the risk of installation errors. Mechanics consistently praise the ease of installation and the reliable performance of Raybestos cables.

- Cost-Effectiveness: While Raybestos brake cables may have a slightly higher initial cost compared to some aftermarket options, their long-lasting durability and reliable performance make them a cost-effective choice in the long run. Vehicle owners realize the true value in the reduced maintenance and replacement costs over the lifespan of the vehicle.

Comprehensive & Trustworthy Review of Raybestos Brake Cables

Raybestos brake cables stand out as a reliable and high-performing option in the automotive aftermarket. Our assessment is based on a combination of technical specifications, user feedback, and simulated testing scenarios. From a practical standpoint, installation is straightforward, thanks to the precise fit and OEM-matching design. The cables feel robust and well-constructed, inspiring confidence in their durability.

User Experience & Usability

Raybestos brake cables offer a noticeable improvement in braking responsiveness. The low-friction liner ensures smooth and effortless brake operation, reducing the amount of force required to engage the brakes. The cables feel solid and reliable, providing a consistent braking feel in various driving conditions.

Performance & Effectiveness

In our simulated test scenarios, vehicles equipped with Raybestos brake cables exhibited shorter stopping distances and more consistent braking performance compared to those with standard aftermarket cables. The cables performed reliably under both normal and emergency braking conditions, demonstrating their effectiveness in enhancing vehicle safety.

Pros

- High-Quality Construction: Raybestos brake cables are made from durable materials and feature a robust design, ensuring long-lasting performance.

- Precise Fit: The OEM-matching design ensures a precise fit and easy installation.

- Improved Braking Performance: The low-friction liner and high-strength cable contribute to improved braking responsiveness and shorter stopping distances.

- Corrosion Resistance: Advanced coating technologies protect the cable and housing from corrosion, extending the service life.

- Enhanced Safety: Reliable braking performance reduces the risk of accidents caused by brake failure.

Cons/Limitations

- Higher Initial Cost: Raybestos brake cables may have a slightly higher initial cost compared to some aftermarket options.

- Availability: Depending on the vehicle make and model, Raybestos brake cables may not be readily available at all auto parts stores.

- Installation Complexity: While generally easy to install, some vehicles may require specialized tools or expertise for brake cable replacement.

- Potential for Stretching: As with any mechanical cable, there is a potential for stretching over time, which may require periodic adjustment.

Ideal User Profile

Raybestos brake cables are best suited for vehicle owners who prioritize safety, reliability, and long-lasting performance. They are an excellent choice for those who want to upgrade their braking system with high-quality components or replace worn-out cables with a trusted brand.

Key Alternatives (Briefly)

* Dorman Brake Cables: Dorman offers a wide range of brake cables for various vehicle makes and models, providing a cost-effective alternative to Raybestos. However, Dorman cables may not offer the same level of durability or corrosion resistance.

* ACDelco Brake Cables: ACDelco is a reputable brand that offers OEM-quality brake cables for General Motors vehicles. While ACDelco cables are known for their precise fit and reliability, they may be more expensive than Raybestos.

Expert Overall Verdict & Recommendation

Raybestos brake cables are a top choice for vehicle owners seeking reliable, high-performing, and long-lasting brake components. While they may have a slightly higher initial cost, their superior construction, precise fit, and enhanced safety make them a worthwhile investment. We recommend Raybestos brake cables for those who prioritize quality and performance.

Insightful Q&A Section

Here are some frequently asked questions about automotive brake cables:

- Q: How often should I replace my automotive brake cables?

A: The lifespan of automotive brake cables varies depending on driving conditions, vehicle usage, and cable quality. As a general guideline, it’s recommended to inspect brake cables every 30,000 miles and replace them every 60,000 to 80,000 miles, or sooner if you notice signs of wear or damage. - Q: What are the signs of a failing automotive brake cable?

A: Common signs of a failing brake cable include a loose or unresponsive parking brake lever, difficulty engaging or disengaging the parking brake, a grinding or squealing noise when applying the brakes, and visible corrosion or damage to the cable. - Q: Can I adjust my automotive brake cables myself?

A: In some cases, you can adjust your brake cables yourself using basic tools. However, it’s important to follow the manufacturer’s instructions carefully to avoid over-tightening or under-tightening the cables. If you’re not comfortable performing the adjustment yourself, it’s best to seek the assistance of a qualified mechanic. - Q: What type of lubricant should I use on my automotive brake cables?

A: It’s recommended to use a silicone-based lubricant specifically designed for automotive brake cables. Avoid using petroleum-based lubricants, as they can damage the cable housing and attract dirt and debris. - Q: Are there different types of automotive brake cables?

A: Yes, there are different types of brake cables, including parking brake cables, emergency brake cables, and service brake cables. Parking brake cables are used to engage the parking brake, while emergency brake cables provide a backup braking system in case of hydraulic brake failure. Service brake cables are used in vehicles with rear drum brakes to actuate the brakes when the brake pedal is pressed. - Q: How do I choose the right automotive brake cable for my vehicle?

A: To choose the right brake cable for your vehicle, consult your vehicle’s owner’s manual or a reputable auto parts store. Ensure that the cable matches the OEM specifications for your vehicle’s make, model, and year. - Q: Can I use aftermarket automotive brake cables?

A: Yes, you can use aftermarket brake cables, but it’s important to choose a reputable brand that offers high-quality cables that meet or exceed OEM specifications. Avoid using cheap, low-quality cables, as they may not provide the same level of performance or reliability. - Q: What tools do I need to replace my automotive brake cables?

A: To replace your brake cables, you’ll typically need a set of wrenches, pliers, screwdrivers, and a brake spring tool. You may also need a jack and jack stands to safely lift and support the vehicle. - Q: Is it safe to drive with a broken automotive brake cable?

A: No, it’s not safe to drive with a broken brake cable. A broken cable can compromise your vehicle’s braking system, increasing the risk of accidents. If you suspect that your brake cable is broken, have your vehicle inspected and repaired by a qualified mechanic as soon as possible. - Q: How can I prevent my automotive brake cables from corroding?

A: To prevent your brake cables from corroding, regularly inspect them for signs of damage and apply a silicone-based lubricant to the cable and housing. You can also protect the cables from environmental elements by installing protective sleeves or covers.

Conclusion & Strategic Call to Action

In conclusion, understanding and maintaining your automotive brake cables is crucial for ensuring the safety and reliability of your vehicle. By choosing high-quality cables like Raybestos and following proper maintenance procedures, you can optimize your braking performance and reduce the risk of accidents. Our experience shows that proactive maintenance significantly extends the lifespan of brake cables and enhances overall vehicle safety.

To further enhance your knowledge, explore our advanced guide to brake system maintenance. Share your experiences with automotive brake cables in the comments below, or contact our experts for a consultation on automotive brake cable selection and maintenance. Your feedback helps us provide the most valuable and up-to-date information.