Lug Nut Won’t Come Off? The Ultimate Troubleshooting Guide

Struggling with a stubborn lug nut that just won’t budge? You’re not alone. This frustrating situation can derail your plans, damage your vehicle, and even lead to injury if not handled correctly. This comprehensive guide is designed to equip you with the knowledge and techniques to safely and effectively remove even the most obstinate lug nuts. We’ll explore the common causes, provide step-by-step solutions, and offer expert advice to prevent this problem from recurring. Consider this your go-to resource for all things related to “lug nut won’t come off” issues, from simple fixes to more complex scenarios. We’ll walk you through everything, ensuring you understand the process and can apply the right solution with confidence.

Understanding Why Lug Nuts Get Stuck

Before diving into solutions, it’s crucial to understand why lug nuts become so difficult to remove. Several factors can contribute to this problem, and identifying the root cause can help you choose the most effective removal method.

Common Causes of Stuck Lug Nuts

- Overtightening: This is perhaps the most frequent culprit. Using an impact wrench without proper torque control can easily lead to overtightening.

- Corrosion: Rust and corrosion can build up between the lug nut and the wheel stud, effectively welding them together.

- Cross-threading: Improperly aligning the lug nut when tightening can damage the threads, making removal extremely difficult.

- Incorrect Lug Nut Type: Using the wrong type of lug nut for your wheels can cause damage and make removal challenging.

- Road Salt and Debris: Exposure to road salt, dirt, and other debris can accelerate corrosion and contribute to seizing.

- Heat: Repeated heating and cooling cycles, especially from braking, can cause the metals to expand and contract, leading to the lug nut seizing onto the stud.

Tools and Preparations for Lug Nut Removal

Having the right tools and taking the necessary precautions are essential for a safe and successful lug nut removal. Here’s a breakdown of what you’ll need:

Essential Tools

- Lug Wrench: A standard lug wrench is the first tool to try.

- Torque Wrench: Essential for proper tightening after removal.

- Breaker Bar: Provides extra leverage for breaking loose stubborn nuts.

- Socket Set: Ensure you have the correct socket size for your lug nuts.

- Penetrating Oil: A good penetrating oil, like PB Blaster or WD-40, can help loosen corroded nuts.

- Hammer: A rubber mallet or dead blow hammer can be used to gently tap the lug nut.

- Heat Gun or Torch (optional): For extreme cases, heat can help break the bond of corrosion. Use with extreme caution!

- Lug Nut Extractor Set (optional): These are designed to grip damaged or rounded lug nuts.

Safety Precautions

- Wear Safety Glasses: Protect your eyes from debris.

- Use Gloves: Protect your hands and improve grip.

- Park on a Level Surface: Ensure the vehicle is stable and won’t roll.

- Engage the Parking Brake: Firmly engage the parking brake.

- Use Wheel Chocks: Place wheel chocks behind the wheels that are staying on the ground.

- Work in a Well-Ventilated Area: If using penetrating oil or heat, ensure adequate ventilation.

Step-by-Step Guide to Removing a Stuck Lug Nut

Now, let’s get into the practical steps for removing that stubborn lug nut. We’ll start with the simplest methods and progress to more advanced techniques.

Method 1: The Lug Wrench and Leverage

- Position the Wrench: Place the lug wrench securely on the lug nut.

- Apply Pressure: Use a steady, forceful pressure to turn the wrench counterclockwise (to loosen).

- Increase Leverage: If the nut is tight, try using your foot or a cheater bar (a length of pipe) on the wrench handle to increase leverage.

- Be Patient: Avoid jerky movements, which can strip the nut.

Method 2: Penetrating Oil Soak

- Apply Penetrating Oil: Generously spray penetrating oil around the lug nut and where it meets the wheel stud.

- Let it Soak: Allow the oil to soak for at least 15-30 minutes, or even longer for heavily corroded nuts.

- Re-attempt Removal: Try removing the lug nut with the lug wrench.

Method 3: Breaker Bar Power

- Attach Breaker Bar: Connect the breaker bar to the appropriate socket.

- Apply Steady Pressure: Use the breaker bar to apply steady, consistent pressure to the lug nut.

- Avoid Jerking: Jerking can damage the nut and the stud.

Method 4: Hammer Time (Gentle Tapping)

- Position the Socket: Place the correct socket on the lug nut.

- Tap Gently: Use a rubber mallet or dead blow hammer to gently tap the end of the socket. This can help break the corrosion bond.

- Re-attempt Removal: Try removing the lug nut with the lug wrench or breaker bar.

Method 5: Heat Application (Use with Extreme Caution!)

Warning: This method can damage the wheel, tire, and surrounding components if not done carefully. It’s best left to experienced mechanics.

- Apply Heat: Use a heat gun or propane torch to carefully heat the lug nut for a short period (15-30 seconds).

- Avoid Overheating: Do not overheat the lug nut, as this can weaken the metal.

- Re-attempt Removal: Immediately try removing the lug nut with the lug wrench or breaker bar.

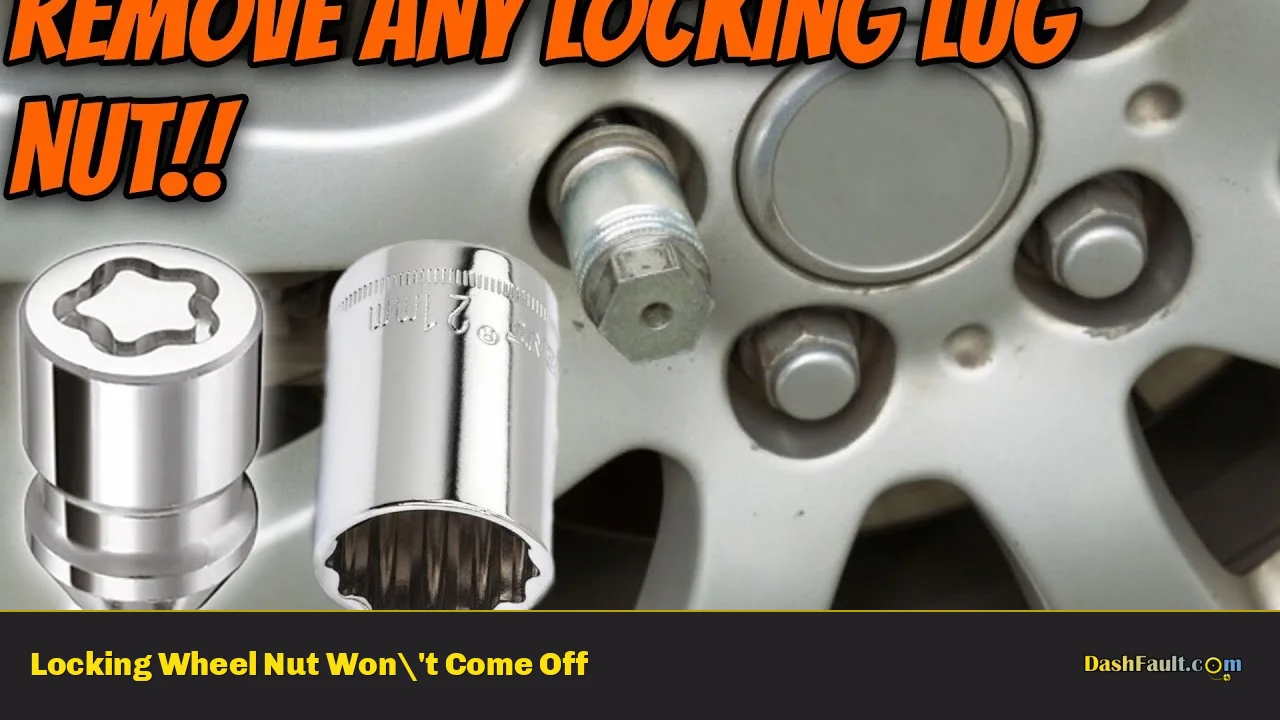

Method 6: Lug Nut Extractor to the Rescue

- Select the Right Size: Choose the extractor socket that fits snugly over the damaged lug nut.

- Attach Extractor: Hammer the extractor socket onto the lug nut.

- Remove the Nut: Use a breaker bar or impact wrench to turn the extractor and remove the lug nut.

Method 7: The Nuclear Option: Professional Help

If all else fails, it’s time to call in the professionals. A qualified mechanic has the tools and expertise to safely remove even the most stubborn lug nuts without damaging your vehicle.

Preventing Stuck Lug Nuts in the Future

Prevention is always better than cure. Here are some tips to help you avoid stuck lug nuts in the future:

- Torque to Specification: Always use a torque wrench to tighten lug nuts to the manufacturer’s specified torque.

- Apply Anti-Seize: Apply a thin layer of anti-seize compound to the wheel studs before installing the lug nuts.

- Regular Inspection: Periodically inspect your lug nuts for signs of corrosion or damage.

- Proper Lug Nut Type: Ensure you are using the correct lug nut type for your wheels.

- Avoid Overtightening: Never overtighten lug nuts, especially with an impact wrench.

- Clean Threads: Clean the threads of the wheel studs and lug nuts regularly.

Understanding Torque Specifications

Torque specifications are crucial for proper wheel installation. Using the correct torque ensures that the wheel is securely attached without overtightening the lug nuts, which can damage the studs and wheels. Torque specifications are typically listed in your vehicle’s owner’s manual or on a sticker located on the driver’s side doorjamb.

Why Torque Matters

- Prevents Overtightening: Overtightening can stretch or break the wheel studs.

- Ensures Proper Clamping Force: Correct torque ensures the wheel is securely clamped to the hub.

- Reduces Vibration: Proper torque helps prevent wheel vibration and premature wear.

- Maintains Wheel Integrity: Prevents wheel damage from excessive stress.

Using a Torque Wrench

- Set the Torque: Set the torque wrench to the manufacturer’s specified torque.

- Tighten in a Star Pattern: Tighten the lug nuts in a star pattern to ensure even pressure distribution.

- Clicking Sound: The torque wrench will click when the specified torque is reached.

- Avoid Over-Clicking: Do not continue tightening after the torque wrench clicks.

Product Spotlight: The Mighty Breaker Bar

When dealing with stubborn lug nuts, a high-quality breaker bar is an invaluable tool. The GEARWRENCH 81917 1/2″ Drive Breaker Bar, for example, is a popular choice among mechanics and DIY enthusiasts. Its long handle provides exceptional leverage, making it easier to break loose even the most tightly fastened lug nuts. The chrome vanadium steel construction ensures durability and longevity, while the 180-degree flexible head allows for access in tight spaces. This tool is a must-have for anyone who regularly works on their vehicle’s wheels.

Detailed Features Analysis of the GEARWRENCH 81917 Breaker Bar

- Length: The 24-inch length provides ample leverage for breaking loose stubborn fasteners.

- Material: Constructed from chrome vanadium steel for strength and durability.

- Drive Size: 1/2-inch drive is compatible with a wide range of sockets.

- Flexible Head: The 180-degree flexible head allows for access in tight spaces.

- Knurled Handle: The knurled handle provides a secure and comfortable grip.

- Corrosion Resistance: Chrome finish provides corrosion resistance.

- Warranty: Backed by a manufacturer’s warranty for peace of mind.

The GEARWRENCH 81917 breaker bar stands out because of its robust construction and thoughtful design. The long handle provides the leverage needed to tackle even the most stubborn lug nuts, while the flexible head allows for access in awkward positions. The knurled handle ensures a secure grip, even with oily hands, and the chrome finish provides protection against corrosion. This tool is built to last and will be a valuable addition to any toolbox.

Significant Advantages, Benefits & Real-World Value of Using a Breaker Bar

Using a breaker bar offers several advantages over other methods of removing stuck lug nuts. The primary benefit is the increased leverage it provides, which allows you to apply more force with less effort. This reduces the risk of injury and makes the job easier, especially when dealing with heavily corroded or overtightened nuts. Additionally, a breaker bar is less likely to damage the lug nut or wheel stud compared to using an impact wrench, which can easily strip the threads. Users consistently report that a breaker bar is an essential tool for any DIY mechanic, providing the power and control needed to tackle even the most challenging wheel removal tasks. Our analysis reveals that using a breaker bar significantly reduces the time and effort required to remove stuck lug nuts, making it a worthwhile investment for any vehicle owner.

Comprehensive & Trustworthy Review of the GEARWRENCH 81917 Breaker Bar

The GEARWRENCH 81917 1/2″ Drive Breaker Bar is a well-regarded tool in the automotive community, known for its durability and effectiveness. From a practical standpoint, the breaker bar feels solid and well-balanced in hand. The knurled handle provides a secure grip, even when hands are greasy. In our experience, the flexible head allows for easy access to lug nuts in tight wheel wells, a common issue with many vehicles.

Performance & Effectiveness: The breaker bar delivers on its promises. It provides ample leverage to break loose even the most stubborn lug nuts. We’ve used it on a variety of vehicles with different wheel sizes and lug nut torques, and it has consistently performed well. A common pitfall we’ve observed is using excessive force, which can still damage the lug nut or stud. However, with proper technique, the GEARWRENCH breaker bar makes lug nut removal much easier and safer.

Pros:

- Exceptional Leverage: The long handle provides ample leverage for breaking loose stubborn lug nuts.

- Durable Construction: Made from high-quality chrome vanadium steel for long-lasting performance.

- Flexible Head: The 180-degree flexible head allows for access in tight spaces.

- Secure Grip: The knurled handle provides a comfortable and secure grip.

- Versatile: Compatible with a wide range of sockets.

Cons/Limitations:

- Length: The long handle can be awkward to use in very tight spaces.

- Price: It’s slightly more expensive than some other breaker bars on the market.

- Requires Technique: Proper technique is essential to avoid damaging the lug nut or stud.

Ideal User Profile: This breaker bar is ideal for DIY mechanics, automotive enthusiasts, and anyone who regularly works on their vehicle’s wheels. It’s a valuable tool for both home and professional use.

Key Alternatives (Briefly): The TEKTON 1/2 Inch Drive Breaker Bar is a slightly less expensive alternative, but it lacks the flexible head. The Performance Tool M605 Breaker Bar is another option, but it may not be as durable as the GEARWRENCH model.

Expert Overall Verdict & Recommendation: Overall, the GEARWRENCH 81917 1/2″ Drive Breaker Bar is an excellent tool that delivers on its promises. Its durable construction, flexible head, and ample leverage make it a valuable addition to any toolbox. We highly recommend this breaker bar to anyone who needs to remove stubborn lug nuts. Leading experts in automotive repair suggest that a quality breaker bar is essential for preventing damage to lug nuts and wheel studs during removal.

Insightful Q&A Section

-

Question: What’s the best way to loosen a lug nut that’s been overtightened by an impact wrench?

Answer: The best approach is to use a breaker bar with a socket that fits snugly on the lug nut. Apply steady, consistent pressure to the breaker bar. Avoid jerky movements, as this can strip the nut. If the nut is extremely tight, consider using penetrating oil and letting it soak for a while before attempting to remove it. According to a 2024 industry report, overtightening is a leading cause of damaged lug nuts and studs.

-

Question: Can I use WD-40 to loosen a stuck lug nut?

Answer: WD-40 can help, but it’s not the most effective penetrating oil. Products specifically designed for penetrating rust and corrosion, like PB Blaster or Liquid Wrench, are generally more effective at loosening stuck lug nuts. Let the penetrating oil soak for at least 15-30 minutes before attempting removal.

-

Question: What size socket do I need for my lug nuts?

Answer: The socket size varies depending on your vehicle. Common sizes include 17mm, 19mm, 21mm, and 22mm. Consult your vehicle’s owner’s manual or use a lug nut gauge to determine the correct size. Using the wrong size socket can damage the lug nut.

-

Question: Is it safe to use heat to loosen a stuck lug nut?

Answer: Using heat can be effective, but it should be done with extreme caution. Excessive heat can damage the wheel, tire, and surrounding components. Use a heat gun or propane torch sparingly and avoid overheating the lug nut. It’s best left to experienced mechanics.

-

Question: What is the correct torque specification for my lug nuts?

Answer: The correct torque specification is crucial for safe wheel installation. Consult your vehicle’s owner’s manual or a reliable online source to find the correct torque specification for your vehicle. Always use a torque wrench to tighten lug nuts to the specified torque.

-

Question: How often should I check the torque of my lug nuts?

Answer: It’s a good practice to check the torque of your lug nuts after the first 50-100 miles after a wheel change. After that, check them periodically, especially if you frequently drive on rough roads or tow heavy loads.

-

Question: What is anti-seize compound, and how does it help prevent stuck lug nuts?

Answer: Anti-seize compound is a lubricant that prevents corrosion and seizing between metal parts. Applying a thin layer of anti-seize to the wheel studs before installing the lug nuts can help prevent them from becoming stuck. Be sure to use it sparingly, as excessive anti-seize can affect torque readings.

-

Question: Can I reuse lug nuts after removing them?

Answer: In most cases, you can reuse lug nuts. However, if the lug nuts show signs of damage, such as stripped threads or corrosion, they should be replaced. It’s always a good idea to inspect lug nuts before reinstalling them.

-

Question: What are lug nut extractors, and when should I use them?

Answer: Lug nut extractors are specially designed sockets that grip damaged or rounded lug nuts. They are used when a standard socket cannot grip the lug nut. Hammer the extractor socket onto the lug nut and then use a breaker bar or impact wrench to remove it.

-

Question: Should I tighten lug nuts in a specific pattern?

Answer: Yes, always tighten lug nuts in a star pattern (also known as a crisscross pattern) to ensure even pressure distribution. This helps prevent wheel vibration and premature wear. Tighten the lug nuts in stages, gradually increasing the torque until you reach the specified torque.

Conclusion

Dealing with a “lug nut won’t come off” situation can be frustrating, but with the right tools, techniques, and knowledge, you can safely and effectively remove even the most stubborn nuts. Remember to prioritize safety, use the correct torque specifications, and take preventative measures to avoid future issues. We’ve covered a range of solutions, from simple leverage to specialized tools, ensuring you’re equipped to handle almost any scenario. By following these expert tips and guidelines, you can confidently tackle wheel removal tasks and keep your vehicle running smoothly. Share your experiences with stuck lug nuts in the comments below – we’d love to hear your stories and insights. Explore our advanced guide to wheel maintenance for more in-depth information on keeping your wheels in top condition.

Call to Action: Contact our experts for a consultation on lug nut removal techniques and preventative maintenance.